Synchrotron light sources (SLS) deliver X-ray beams with high brilliance to end stations, where experiments from macromolecular crystallography to scanning X-ray nano-probe are conducted. All SLS applications would benefit from highly transparent, compact, fast, and reliable X-ray beam position monitors (XBPMs) with high lateral resolutions, stability over time, fast dynamics, and continuous operation. Diamond has been until recently the material of choice for hard X-ray (from ~4 keV) in-beam transparent position monitors due to its low absorptivity, extremely high radiation hardness and high thermal conductivity.

Single crystal diamond (sc-diamond), as well as polycrystalline diamond on silicon (pc-diamond) XBPMs is now commercially available. However, the desired device properties of sc-diamond are not obtained on a commercial scale due to the use of thick substrates with high absorption, and availability of samples only smaller than 10 x 10 mm2 . Whereas use thin pc-diamond on Si allows obtaining thin/highly transparent membranes but the material shows a high density of defects that result in poor electrical properties. XBPMs made of Silicon Carbide (SiC) allow overcoming both issues while providing similar thermal and mechanical properties as their diamond counterparts. The first fabricated SiC XBPMs, realized thanks to a newly developed doping selective electrochemical etching process, have demonstrated the potentialities of this new XBPM material, specifically showing:

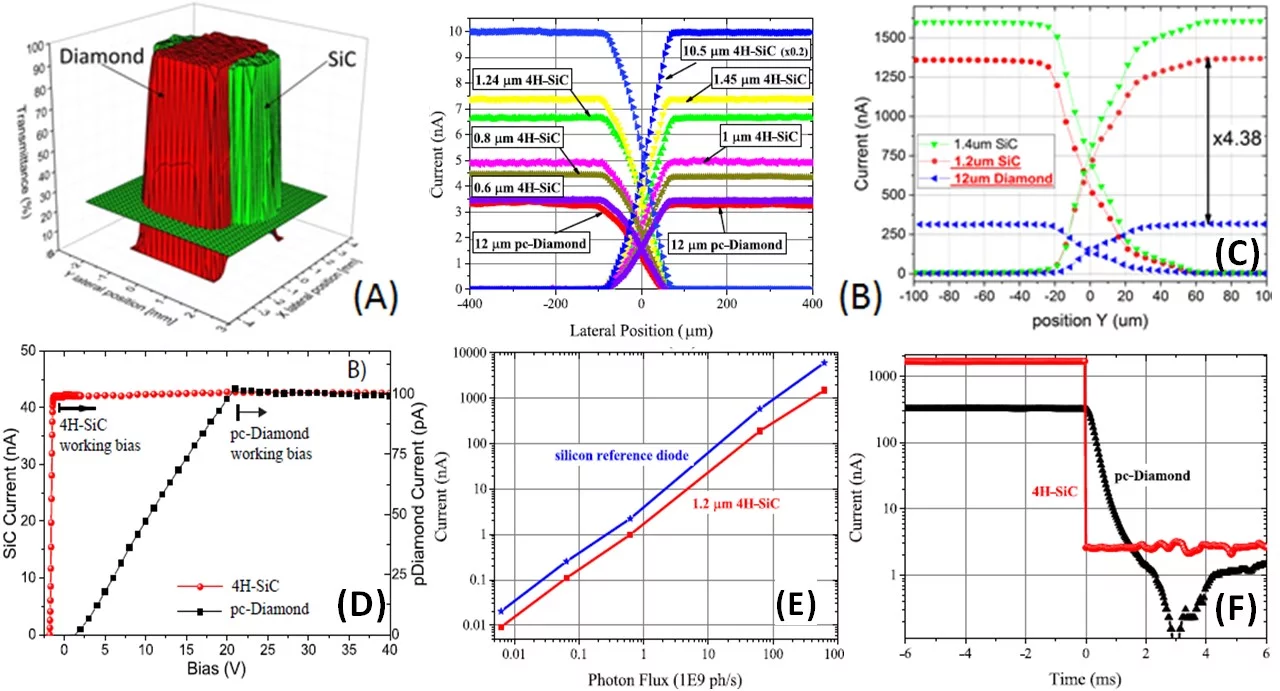

- Transparencies equivalent to commercial polycrystalline XBPM devices (RIGI, from DECTRIS™) and more than 5 times superior when compared to single-crystal ones (from CIVIDEC™), i.e. a transparency >98% at 12.4 keV, see Fig.1A.

- Superior and higher (x4.38) signal uniformity when compared to RIGI devices, see Fig.1B and 1C.

- Saturated charge collection efficiency already at zero external bias, Fig.1D, thanks to the internal built-in voltage of the pin diode.

- Linearity of the electrical response over more than 4 orders of magnitude, Fig.1E.

- Electrical response to beam variation below micro seconds, more than 3 orders of magnitude better as compared to RIGI devices, fig.1E.

- Realization of these potentialities in the first permanent installation performed at the microXAS beamline, specifically demonstrating:

a Direct optical view of the beam, thanks to the fluorescence properties of SiC.

b Monitoring of the beam shift when changing the photon wavelength.

Given the obtained results and availability of electronic grade epitaxies on up to 8 inch wafers, we expect Silicon Carbide to substitute diamond in most beam monitoring applications.