Metal assisted chemical etching (MacEtch) is a plasma less nanofabrication method, consisting of a local electrochemical reaction at the catalyst surface. The metal catalyst sinks into the silicon substrate as it etches the substrate around itself. This allows for very selective etching, resulting in very deep, very small structures with straight and smooth sidewalls. We demonstrated that this method can create super high aspect ratio (1:10’000) structures with feature sizes down to 10 nm.

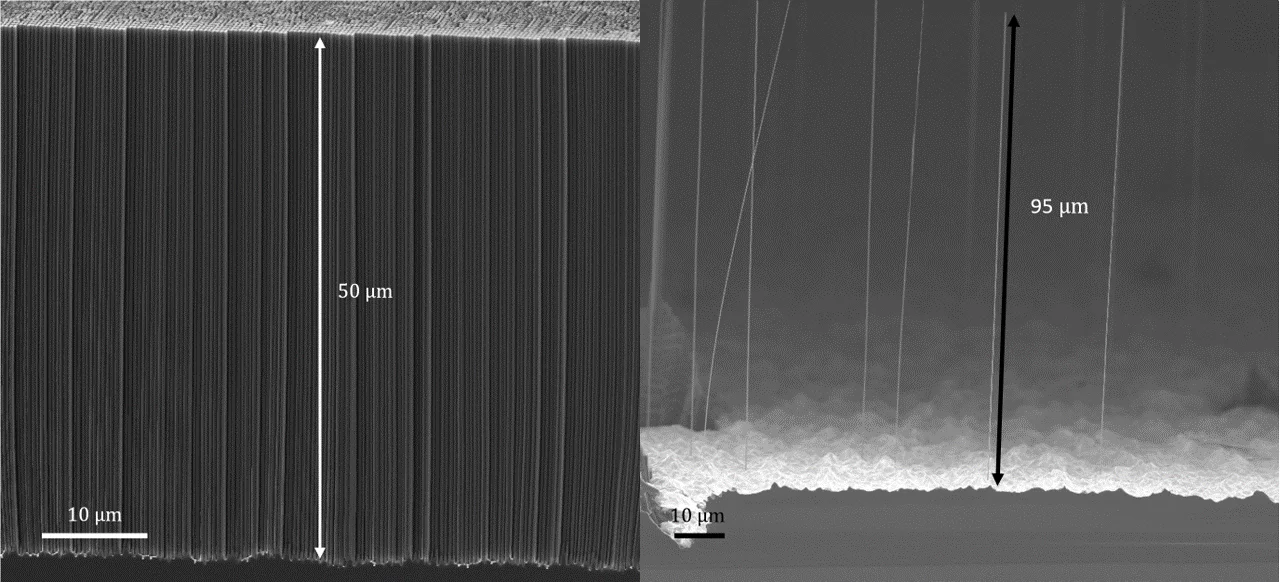

The MacEtch reaction to etch silicon requires noble metals as catalyst – e.g. Pt – an oxidizer – e.g. H2O2 or O2 – and an etchant – e.g. HF. The reaction can occur in liquid or in gas. As the technology is still new and it’s understanding, especially in vapor phase, is limited, answering the fundamental questions that are open about MacEtch supports the development of this technology further. On the application side, we are developing suitable patterning methods for the metal catalyst in order to address different needs and different scales. For example, isolated high aspect ratio nanowires (see Figure b) can be used for magnetic force microscopy as cantilevers. While very dense regular patterns such as gratings (see Figure a) with submicron feature sizes are required for x-ray optics. Both applications are currently limited by the availability of these nanostructures and would greatly benefit in a reduction of feature size and an increase of aspect ratio. Metal assisted chemical etching (MacEtch) elegantly solves both these problems at once pushing nanofabrication beyond its current limit. Moreover, the catalyst is located at the bottom of the trenches at the end of the process, offering a very convenient seed layer for Au electroplating, which is necessary to create absorbing structures for hard x-ray optics.

Publications

- Romano, L., Vila-Comamala, J., Jefimovs, K., & Stampanoni, M. (2020). High‐aspect‐ratio grating microfabrication by platinum‐assisted chemical etching and gold electroplating. Advanced Engineering Materials, 2000258.

- Romano, L., & Stampanoni, M. (2020). Microfabrication of X-ray optics by metal assisted chemical etching: a review. Micromachines, 11(6), 589 (23 pp.).

- Romano, L., Kagias, M., Vila-Comamala, J., Jefimovs, K., Tseng, L. T., Guzenko, V. A., & Stampanoni, M. (2020). Metal assisted chemical etching of silicon in the gas phase: a nanofabrication platform for X-ray optics. Nanoscale Horizons, 5(5), 869-879.

Funding

- ERC-PoC-2016 MAGIC grant Nr. 727246;

- SNI NanoArgovia Grant 13.01 “NANOCREATE”

- SNI PhDSchool Project Nr. P2205 MAGNET