In pulsed laser deposition the use of a rectangular or elliptical beam spot with a non 1:1 aspect ratio leads to the so called flip-over effect. Here, the longest dimension of the laser spot results in the shortest direction of plasma plume expansion. This effect has been mainly reported for vacuum depositions of single element targets and is particularly noticeable when the aspect ratio of the beam spot is large.

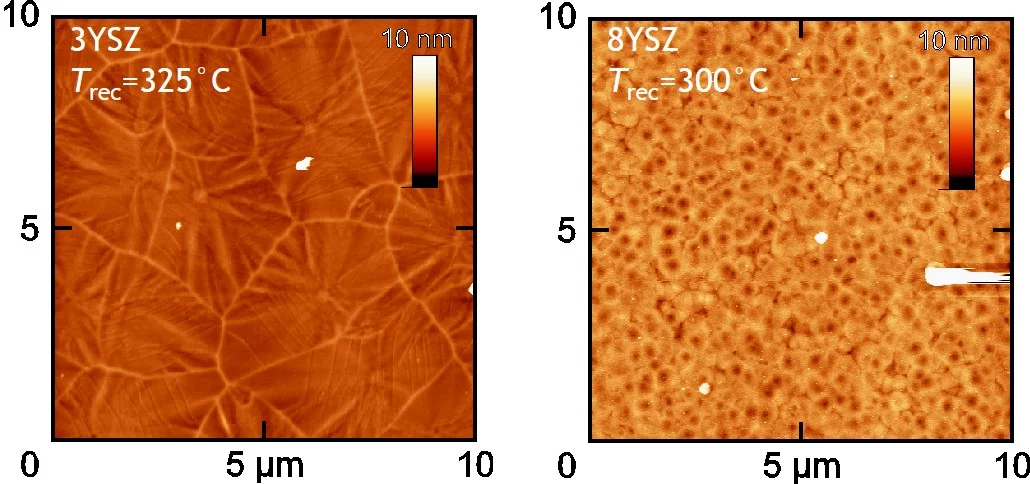

The crystallization kinetics of amorphous 3 and 8 mol% yttria stabilized zirconia (3YSZ and 8YSZ) thin films grown by pulsed laser deposition (PLD), spray pyrolysis and dc-magnetron sputtering are explored. The deposited films were heat treated up to 1000 °C ex situ and in situ in an X-ray diffractometer. A minimum temperature of 275 °C was determined at which as-deposited amorphous PLD grown 3YSZ films fully crystallize within five hours. Above 325 °C these films transform nearly instantaneously with a high degree of micro-strain when crystallized below 500 °C. In these films the t′′ phase crystallizes which transforms at T > 600 °C to the t′ phase upon relaxation of the micro-strain. Furthermore, the crystallization of 8YSZ thin films grown by PLD, spray pyrolysis and dc-sputtering are characterized by in situ XRD measurements. At a constant heating rate of 2.4 K min−1 crystallization is accomplished after reaching 800 °C, while PLD grown thin films were completely crystallized already at ca. 300 °C.

Facility: ENE, ETH, LMX, Thin Films and Interfaces

Reference: D. Stender, R. Frison, K. Conder, J. L. M. Rupp, B. Scherrer, J. M. Martynczuk, L. J. Gauckler, C. W. Schneider, T. Lippert and A. Wokaun, Phys. Chem. Chem. Phys., 17, 18613-18620 (2015)

Read full article: here