Magnet and sample insert specifications

| Description | Value |

|---|---|

| Maximum field along beam direction | 7 T |

| Maximum field in vectorial mode (square in horizontal plane) | 2 T |

| Remanent field | up to 10 mT |

| Maximum field sweep rate for field along beam | 2 T/min |

| Maximum field sweep rate in vector mode | 0.36 T/min |

| Sample temperature range | 2 K - 350 K |

| Detection modes | Total electron yield (TEY). If requested, total fluorescence yield (TFY) or transmission can be acquired in parallel with TEY |

In-situ sample preparation system

Note that beamtimes requiring in-situ sample preparation are scheduled, if possible, such that the sample preparation system can be accessed off-line a few days during the week preceding the beamtime. These preparation shifts do not count on the total proposal shift request. The shift request concerns only the actual beamtime.

The in-situ preparation system is open for:

a) expert users

By expert users we understand user groups with a strong background in Surface Science and daily experience in surface preparation and STM/AFM (if requested). For these users we provide half a day introduction to the X-Treme preparation system that will be given during the week preceding the beamtime. User support will be given during the beamtime, as for any user group.

b) non-expert users

These groups want to benefit from the possibility of in-situ UHV sample preparation without themselves having a strong background in Surface Science. In order to use the beamtime optimally, we imply that they collaborate with either one of the beamline consortium groups, namely the group of Harald Brune at EPFL (contact: stefano.rusponi@epfl.ch) or the Microscopy and Magnetism group at PSI (contact: cinthia.piamonteze@psi.ch or jan.dreiser@psi.ch). We encourage to get into touch with us before beamtime proposal submission.

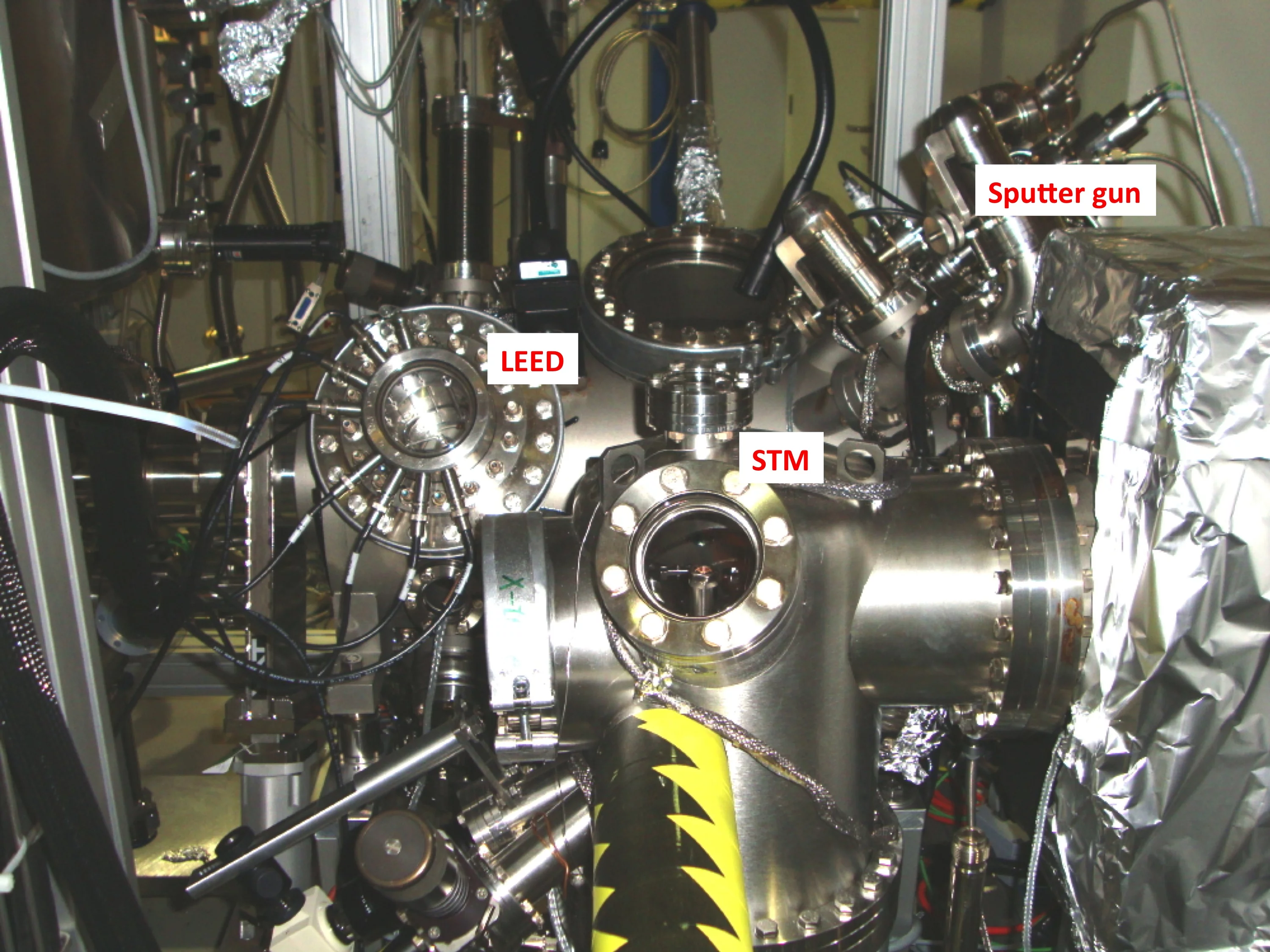

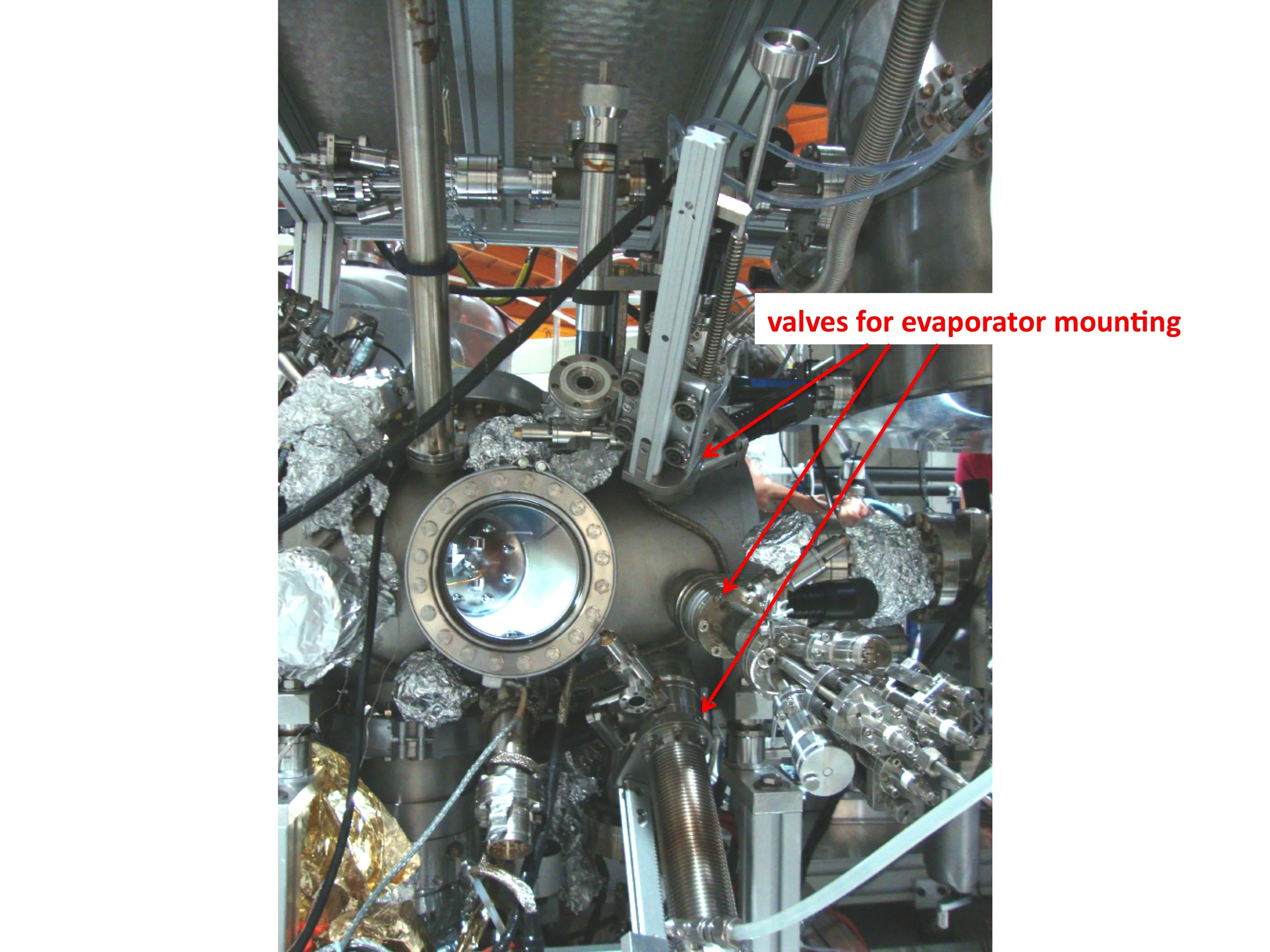

The in-situ sample preparation system is equipped with:

- heating cooling stage (20-1500K)

- Omicron variable temperature STM

- metal evaporator (Omicron Triple EFM)

- molecular evaporator (Kentax TCE-BSC 3cell with double power supply)

- Auger spectrometer

- sputter gun

- quartz balance

The following items are not provided by the beamline:

- plates. Please see this link for the plate design we use which has small modifications compared to the Omicron design. The most important difference is that the plate sides should be straight and not have a wider part close to the handle as in the Omicron design. Contact your local contact if it's the first time using these plates. We recommend plates made of Mo or Ta.

- Evaporants. Please bring your own evaporant material (rods/powders). The beamline does not have a controlled stock for that.

- Crucibles. If crucibles are necessary, the user should bring their own, even if the beamline evaporators are to be used. In this case please check the specifications in the evaporator links above to buy a compatible crucible.

End-station sketch

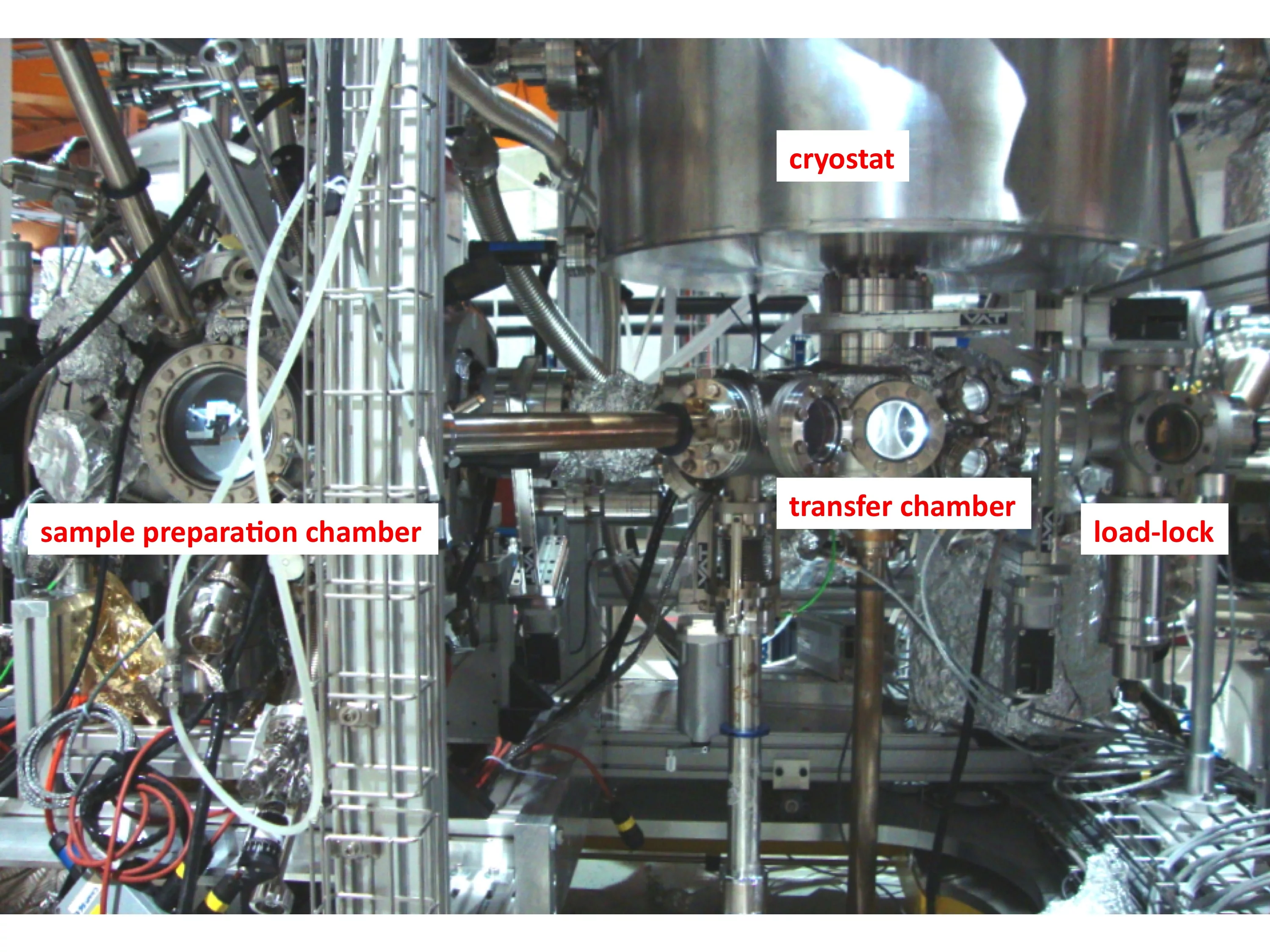

The drawing and picture below shows an overview of all chambers used for sample transfer and preparation.

- Ex-situ samples are loaded in the load-lock and after ~5 hours of pumping they are loaded in the transfer chamber and up to the cryostat.

- Sample transfer to the cryostat can be done only when the sample insert is at room temperature. Warm up of the sample insert to room temperature takes between 1 and 1.5hrs.

- See the desing for standard and in-situ types of sample holders

- More information on load-lock and transfer chamber follow below.

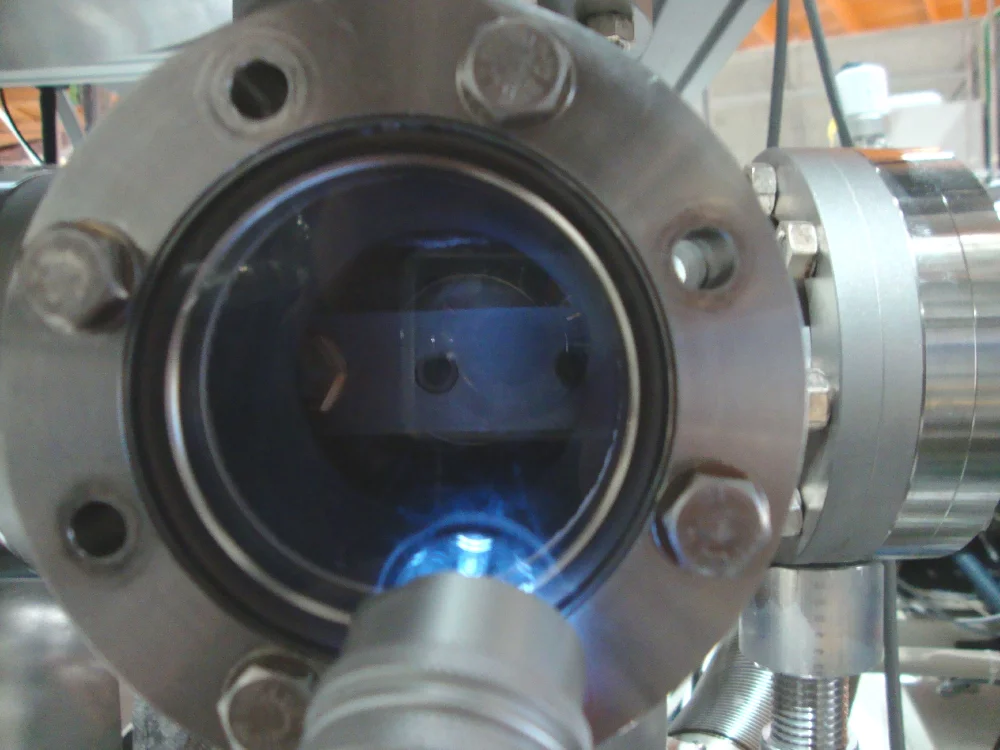

Load-lock

The load-lock consists of a CF63 cross with space to mount 2 to 3 sample holders. The load-lock should be pumped for at least 5 hours before loading the sample.

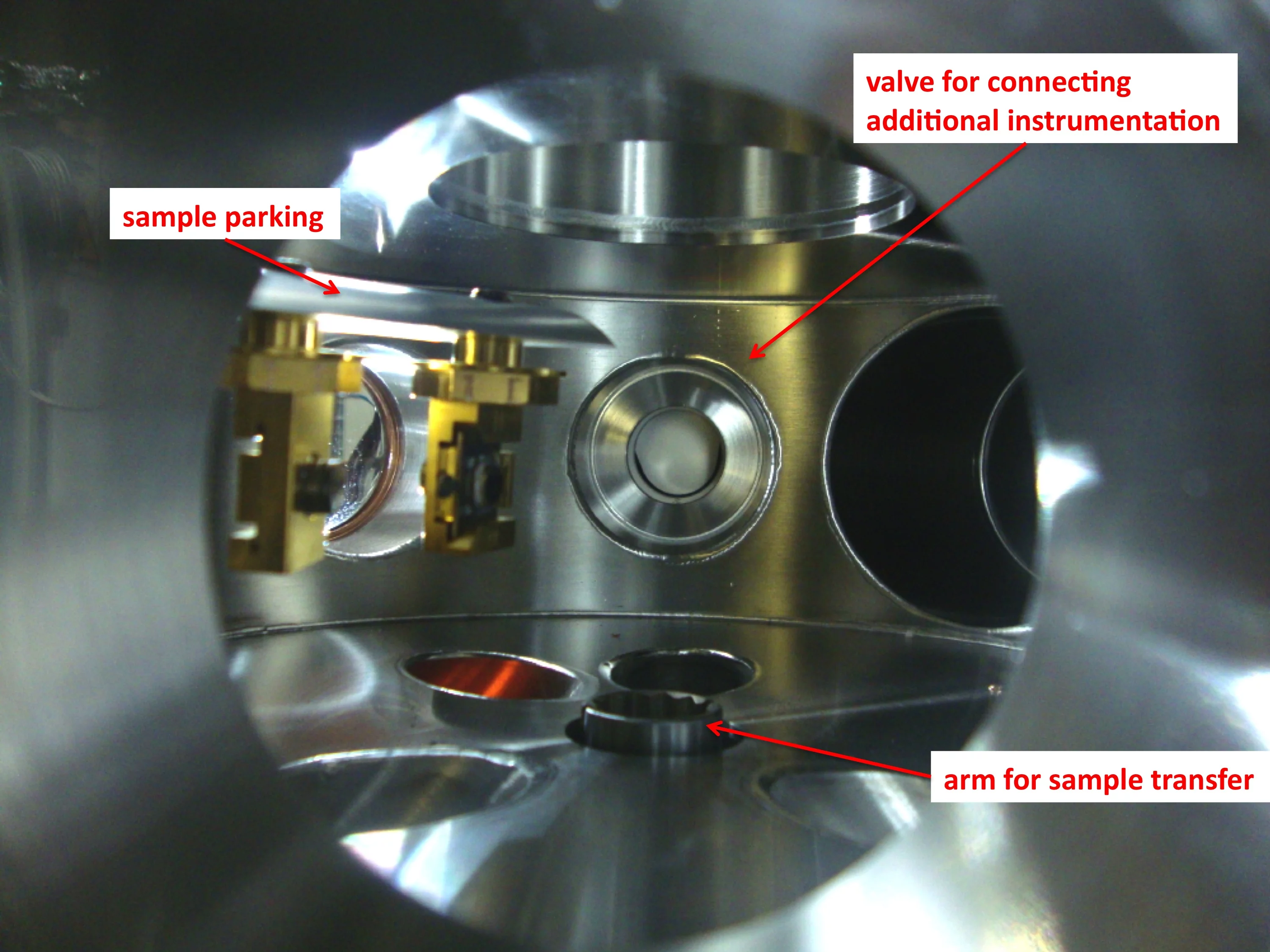

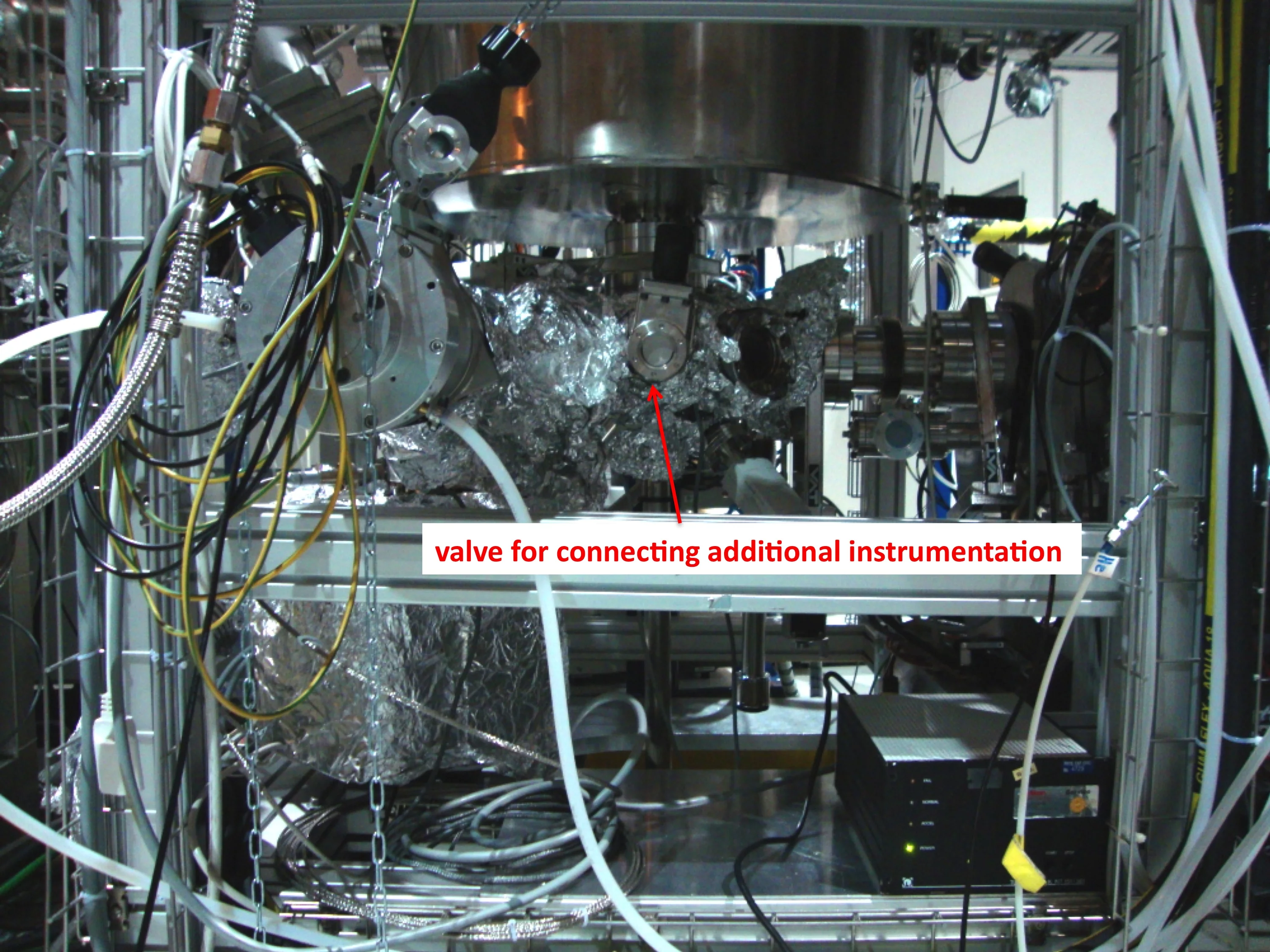

Transfer chamber

The transfer chamber is the intermediate chamber making the connection between load-lock, cryostat and sample preparation system. It is always kept in vacuum and it has a parking stage to store sample holders while another one is being measured and the load-lock is being pumped.

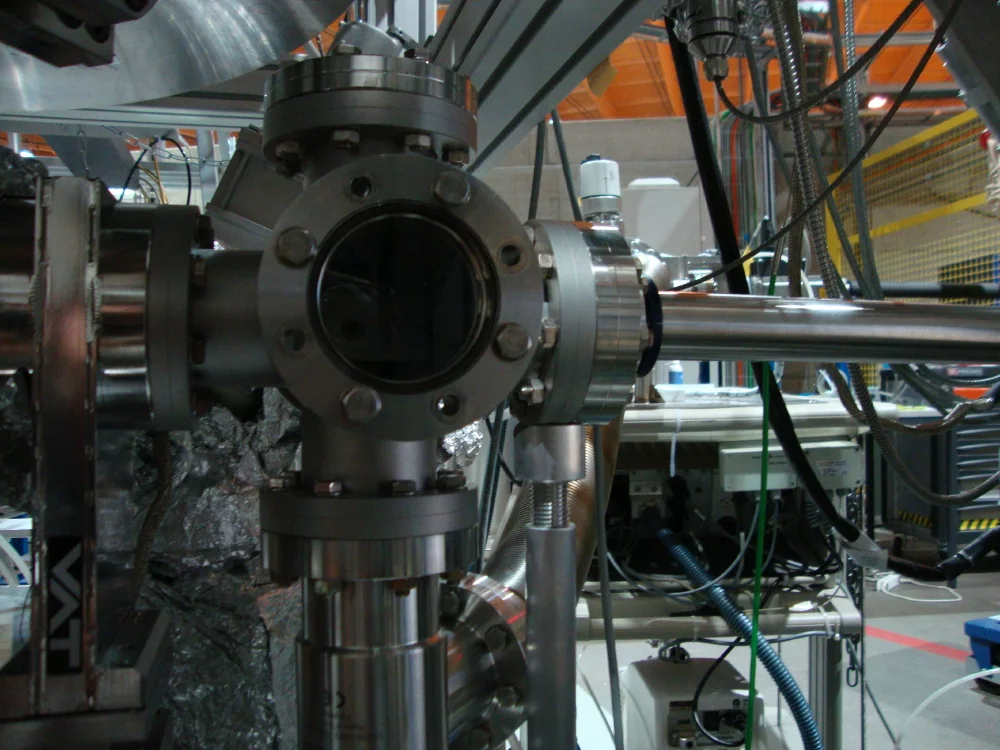

As shown in the figure below the transfer chamber has a CF40 manual valve where one can connect additional user instrumentation, as for example a vacuum suitcase, without the need of breaking the vacuum of the transfer chamber.

Sample holders

Standard sample holder

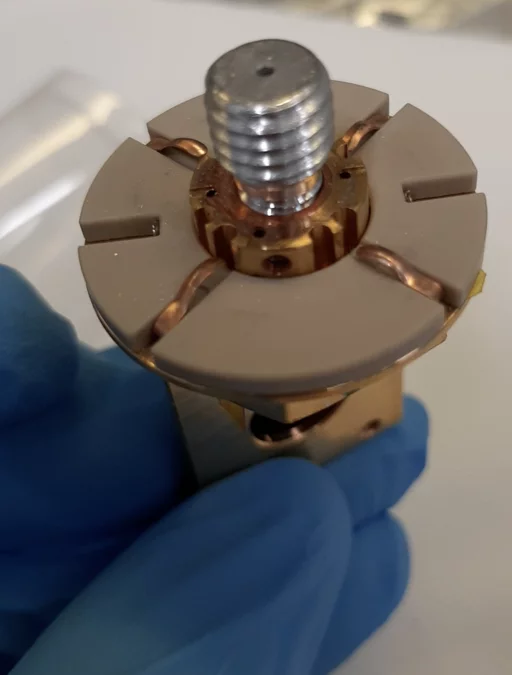

The standard X-Treme sample holder is shown in the picture below (click on the image to zoom):

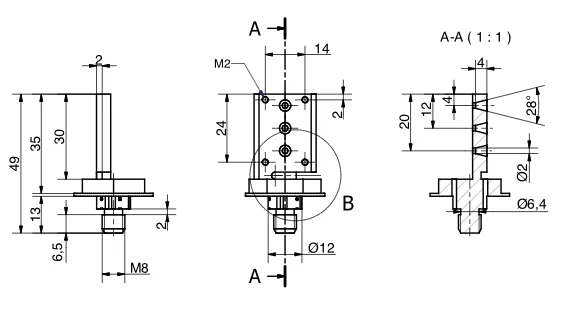

A drawing of the sample holder is given below (click on the image to zoom):

The sample holder accommodates several samples at once. The three holes in the center can be used for transmission measurements.

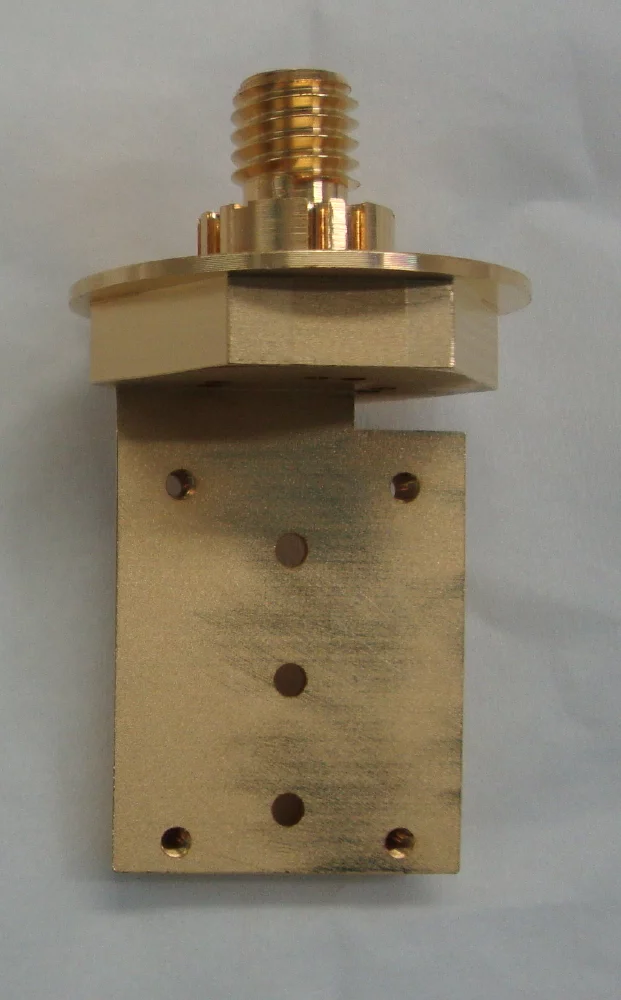

Electrical contact sample holder

The sample holder with electrical contact has the same design as the standard sample holder but with an insulating disk on top and 4 isolated spring contacts which can be wired to the sample or to an additional detector as a photodiode, for example.

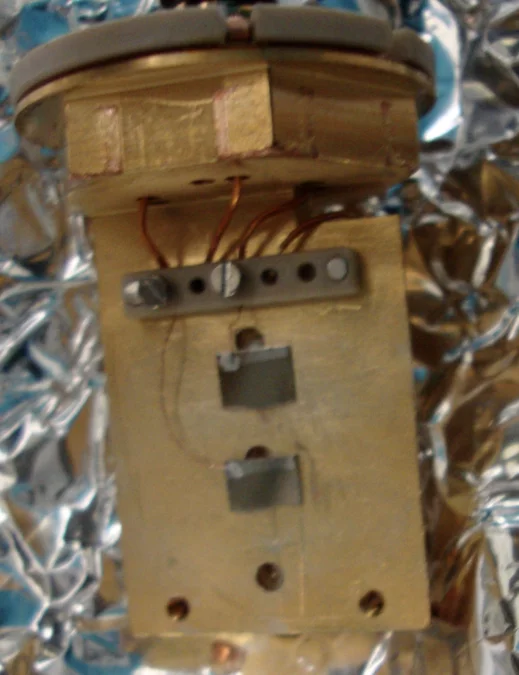

Sample holder for in-situ sample preparation

The drawings below (click on the images to zoom) show the design of the shuttle sample holder to accomodate the omicron-type plates (drawing pdf download here, download .stp file here). This kind of sample holder and the plates are to be used if in-situ sample preparation is required. The in-situ sample preparation system is open only for expert users. Please contact the beamline scientists if in-situ sample preparation is required.