The following facilities are operated by SACRE:

Curently used facilities

ARAGO

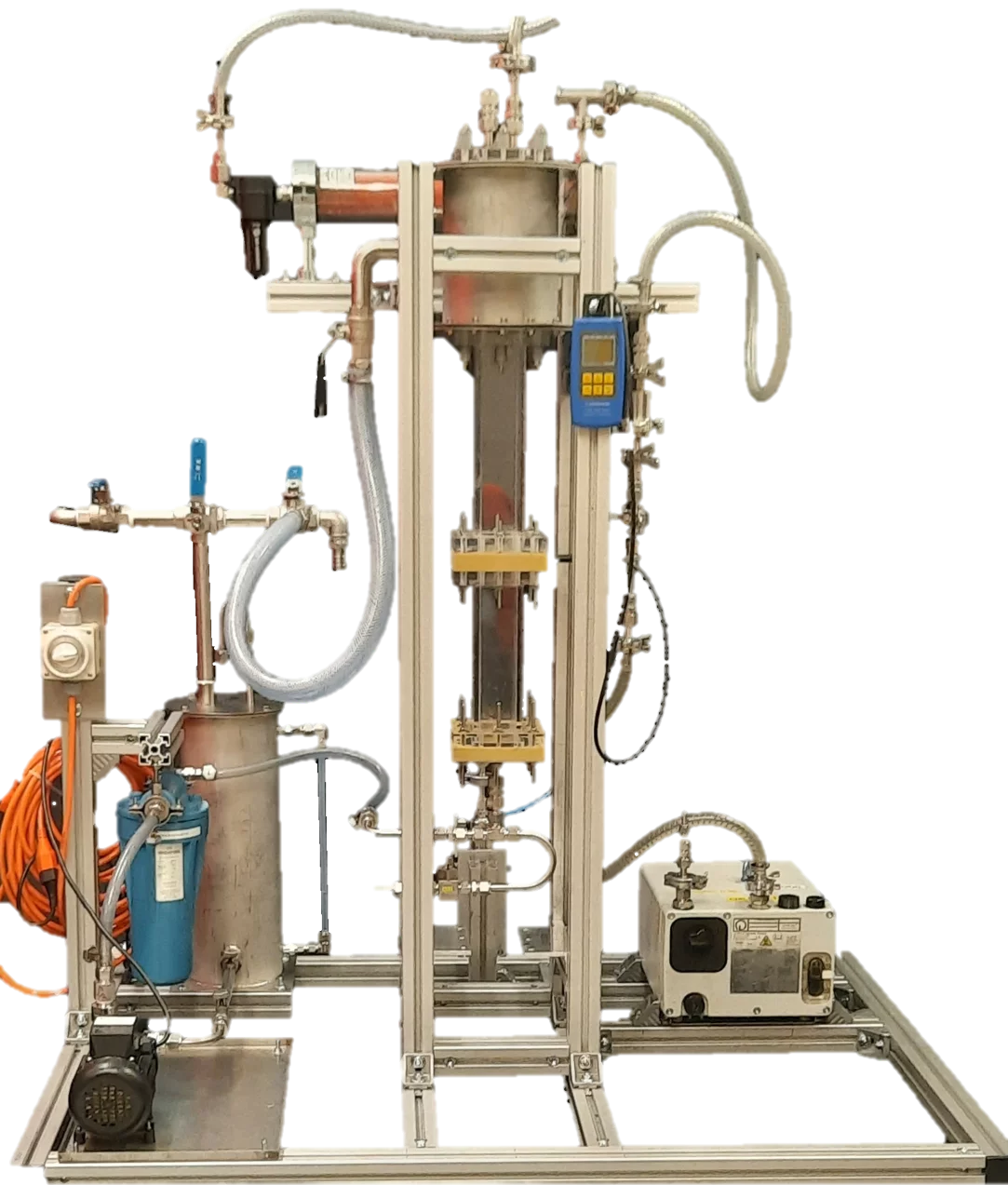

The Aerosol Retention Assessment for Gas-liquid flOws (ARAGO) facility is a setup to perform high-resolution experiments on aerosol retention via pool scrubbing. The atomizer aerosol generator system introduces the particles in the 550 mm height and 50 mm square section test column via a vertical injector. The wire-mesh tomographic sensor located 200 mm over the injection point allows for high-speed visualization of transient gas fractions, and aerosol mass wakes of the multiphase flow. The highest possible spatial resolution is 1.0 mm between wires. In its bubble column configuration, the wire-mesh sensor can measure the integral retention in the test section. The main pumps inject the water at the bottom of the facility introducing liquid-phase velocity in the system. The full range of two-phase flow regimes can be reproduced. The circulation can operate in close (recirculation) or open mode to keep constant the water conductivity in the test section. The aerosol is extracted from the top of the column and flows through a diffusion dryer to remove the humidity so that its concentration and size distribution can be characterized with suitable aerosol measurement techniques.

DRAGON

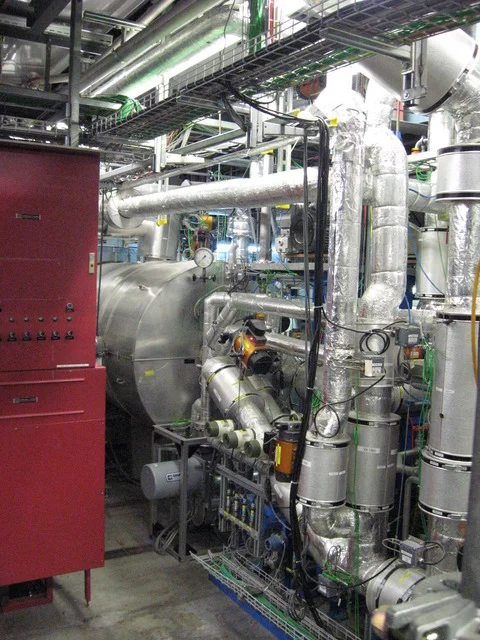

(Diverse purpose aerosol generation facility) is a multi purpose aerosol generation facility to provide carrier gas-aerosol flow to various experimental facilities. It has been used in connection with such facilities as CONGA, POSEIDON, ARTIST and VEFITA for investigation of aerosol and iodine transport for source term analysis in several international and national research programs. DRAGON combines the aerosol generation, steam and air/nitrogen supply, heating, heat removal, and aerosol measurement systems. It has a maximum operation pressure of 10 bar and temperature of 330°C. DRAGON can be used for the generation of a wide range of aerosols with different size distributions and compositions by several different aerosol generation methods: plasma torches, fluidized bed generators, two-fluid nozzles, atomizers, and dry powder feeders. In addition, different species of iodine may also be generated and measured. The aerosol measurement devices include, e.g., low-pressure impactors, optical particle counters, electrical low-pressure impactors, condensation nucleus counters, photometers, and filters.

ISOLDE

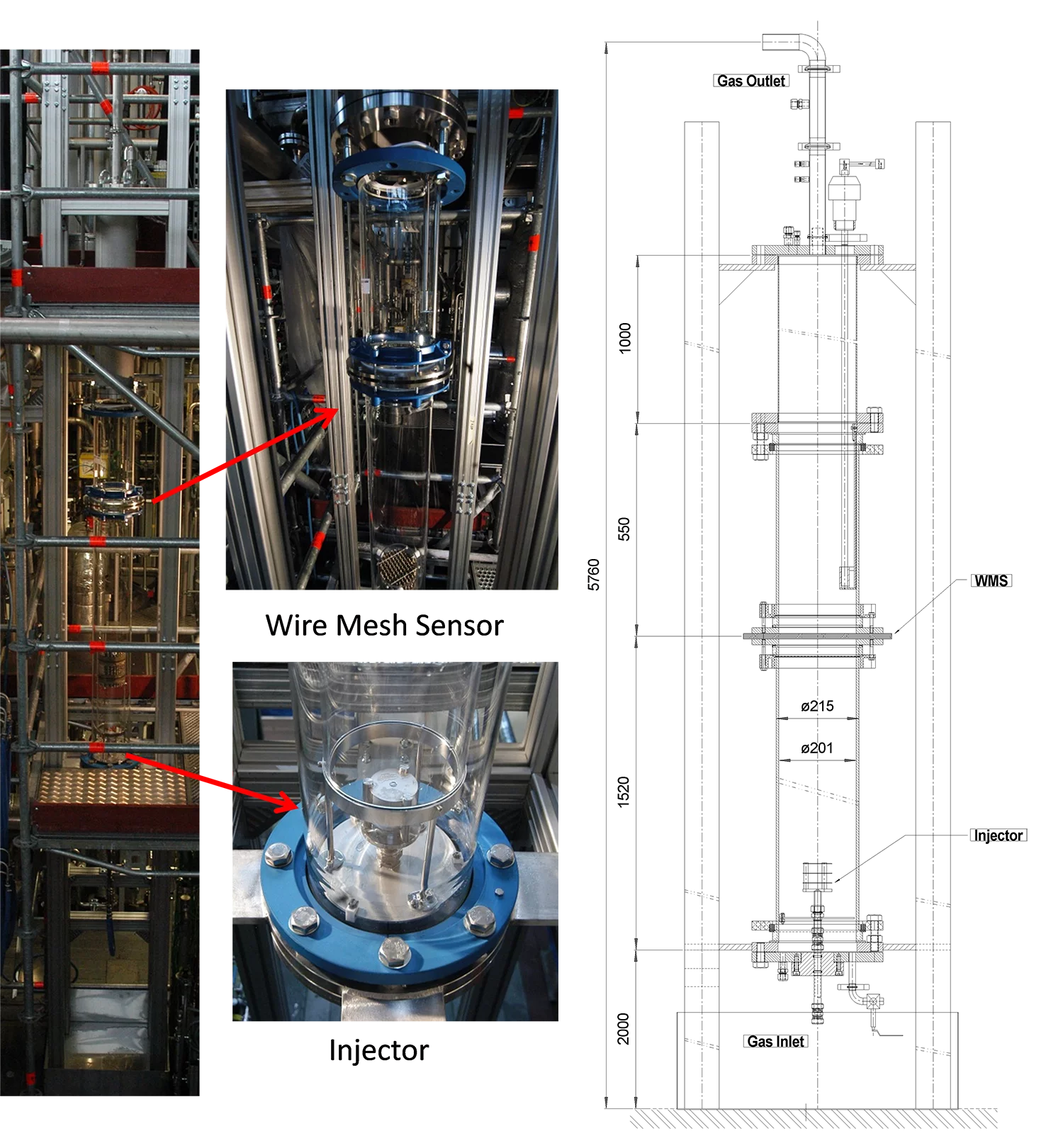

ISOLDE is a further development of the Mini-VEFITA facility to quantitatively investigate two-phase flow gas-liquid flows with focus on the mass transfer of gaseous iodine species to the liquid. The test section has consists of two cylindrical borosilicate glass tubes with 0.2 m in diameter and a height of 1.5 m and 0.5 m and a 1 m long stainless steel outlet section. A three-layer wire-mesh sensor (WMS) with a high temporal resolution of 2.5 kHz and a spatial resolution of 3.0 mm is installed at a height of 1.5 m. The exchangeable gas injector can be moved vertically up and down inside the glass cylinder in order to take measurements at different axial distances to the injector with the WMS. The facility can be operated at ambient pressure and at water temperatures up to boiling conditions (about 98 °C). Non-condensable (NC) gas (air or nitrogen) or mixtures of steam and NC gas can be used at gas temperatures of up to 165 °C and pressures upstream the injector of 6.0 bar(g), allowing chocked flow conditions at the injector. The mass flow rates of NC gas and steam are 0-45 kg/h and 0-12 kg/h, respectively. Different chemicals can be added to the scrubber water to adjust the pH value. The facility is instrumented to measure temperatures, flow rates, pressures, the water level swell and collapsed level and the hydrodynamics of the flow regime.

PRECISE

The PRECISE facility is designed to study the reflux condensation phenomenon which occurs inside steam generator tubes of a pressurized water reactor (PWR) during design basis (DBA) and severe accidents. Reflux condensation is capable of removing residual decay heat from the reactor coolant system (RCS) thereby suppressing or, at least, delaying the core uncovery in a hypothetical loss of coolant accident (LOCA). A large number of studies concerning reflux condensation were done assuming no core damage conditions. In the PRECISE facility, we address severe accident scenarios where the reflux condensation process is influenced by the presence of noncondensable gases, such as hydrogen produced from oxidation of the fuel cladding.

TRISTAN

The TRISTAN (Tube Rupture In Steam generator multi-phase flow investigations) is a versatile facility for the investigation of gas-water two-phase flow hydrodynamics. It is a rectangular steel channel of a square cross section of 0.5 x 0.5 m and an overall height of 6.2 m. Two Wire-Mesh Sensors (WMS) are used to characterize the interfacial structure of the two phase flow with high temporal (1 kHz) and spatial (3 mm) resolution. The facility is operated under ambient conditions.

TRISTAN was designed and constructed to characterize two-phase flow hydrodynamics in a steam generator of a pressurized water reactor under steam generator tube rupture conditions when the secondary side of the steam generator is filled with water. For this application, the facility was equipped with a tube bundle consisting of 221 stainless steel tubes. Tube breaks may be installed at different elevations to feed air or nitrogen into the main flow channel. The tube bundle may be removed and replaced with, e.g., a single tube, or any other internals depending on the application.

VEFITA

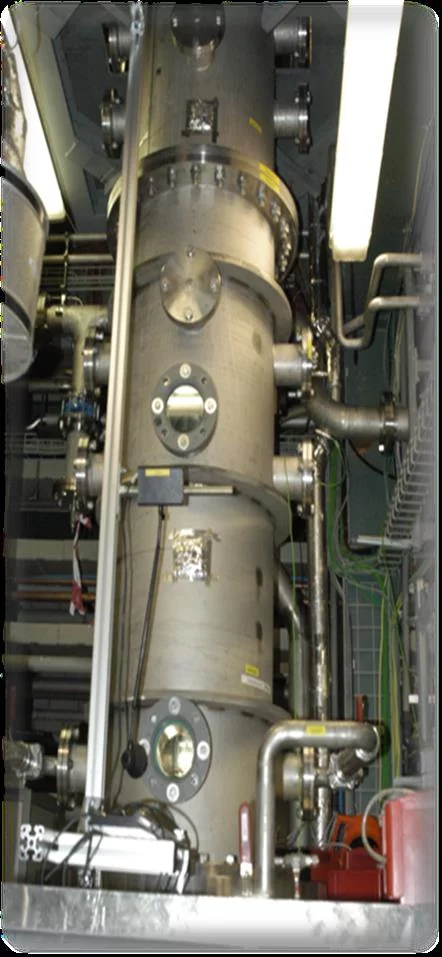

VEFITA (Venting Filter Assessment) is a facility for the investigation of the filtered containment venting systems (FCVS). VEFITA is a full-height, reduced diameter mock-up facility of a wet scrubber consisting of an inlet gas sparger assembly, flow conditioning elements, and a droplet separator. The facility can be operated at a high pressure up to 4.5 bar(a) with the inlet pressure of 10 bar(a). Steam, nitrogen and a mixture of the two can be used with flow rates up to 1200 kg/h. The desired test aerosols are generated in the DRAGON aerosol generation facility, and they are mixed with the steam/nitrogen flow before being fed into the test facility. Different aerosol compositions and size distributions may be used, including soluble and insoluble aerosols as well as monodisperse spherical test aerosols. Similarly, different species of iodine may be generated and fed into the facility along with the steam/nitrogen mixture. For the determination of the decontamination factor, the concentration of aerosols and iodine are determined at the test section inlet and outlet. VEFITA is used both in international and national projects for the investigation of thermal-hydraulic behaviour of FCVS, as well as iodine and aerosol retention in the FCVS.

Mini-VEFITA

The Mini-VEFITA is a small-scale pool scrubbing test facility used for determination of retention of iodine species, e.g., elemental iodine and methyl iodide, in aqueous solutions. The facility consists of a 1.5 m borosilicate glass tube of 0.2 m inner diameter. The geometry of the facility internals can be easily modified. Presently, the facility is equipped with the internals of a filtered containment venting system (FCVS) consisting of: a) an injection orifice with the diameter of 10 mm with 3 perforated impaction plates designed to break-up the initial gas globule; b) an acrylic glass riser of 0.15 m inner diameter; and c) a Sulzer Chemtech mixing element, i.e., a stainless steel mesh designed for optimized bubble breaking. Internals are according to commercially employed FCVS installed in Swiss nuclear power plants (Jacquemain et al., 2014). The vessel is connected to a nitrogen source, steam generator, and an iodine generator. The transparent walls enable visual observation of the hydrodynamics in the pool, and the measurement of iodine / iodide concentration in the inlet and outlet gas are used for determination of the retention of iodine species in the pool. The effect of flow regime, pool temperature, chemistry, and residence time on retention of iodine species are investigated as well as different additives are tested for improved retention of gas phase iodine species.

Formerly used facilitites

DIANA

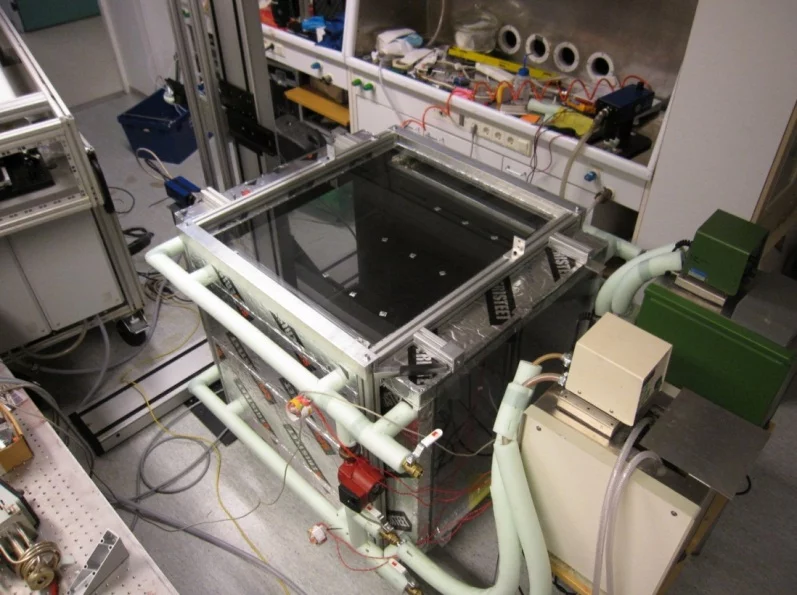

The DIANA Facility is a formerly used facility. DIfferentially heated cavity with Aerosol in NAtural convection (DIANA) facility was constructed to investigate the particle deposition on the walls and floor of a Differentially Heated Cavity (DHC) and to improve understanding of particle retention in a containment building during a hypothetical severe accident conditions. It contains a cubic 0.7 m edge length cavity with two vertical isothermal heated and cooled walls. By changing the temperature difference between the isothermal walls, the Rayleigh number of the turbulent natural convective flow inside the cavity can be modified. The DIANA has been used to measure the deposition of spherical monodisperse SiO2 particles with diameters 0.5, 1 and 2.5 μm with Rayleigh numbers varying between 3x108 and 109 (Kalilainen et al., 2016; Kim, 2017). Online measurements of the particle concentration in DIANA atmosphere have been conducted using both Tapered Element Oscillating Microbalance (TEOM) and Electrical Low Pressure Impactor (ELPI). The optical access through the glass walls of DIANA also allows flow field measurements with devices like Particle Image Velocimetry (PIV) (Kalilainen et al., 2016). The measurement results of the particle depletion were compared to particle tracking simulation data, obtained using a validated Computational Fluid Dynamics (CFD) simulation of the experimental cavity (Dehbi et al., 2017).

Dehbi, A., Kalilainen, J., Lind, T.M., Auvinen, A., 2017

A Large Eddy Simulation of Turbulent Particle-Laden Flow inside a Cubical Differentially Heated Cavity

Journal of Aerosol Science 103, 67–82

Kalilainen, J., Rantanen, P., Lind, T.M., Auvinen, A., Dehbi, A., 2016

Experimental Investigation of a Turbulent Particle-Laden Flow inside a Cubical Differentially Heated Cavity

Journal of Aerosol Science 100, 73–87

Kim, H., 2017

Particle depletion measurements and simulations of aturbulent particle-laden flow inside a cubical differentially heated cavity

MSc thesis, ETHZ.