A new 3D printing method combining steel foils and copper powders leads to the emergence of a BCC phase. This finding sheds light on phase evolution in multi-material metal printing.

The formation mechanism of a Fe-rich body-centered cubic (BCC) phase in multi-material metal parts was investigated using a hybrid additive manufacturing approach. By combining laser powder bed fusion (L-PBF) with thin 316L steel foils deposited on CuCrZr substrates, detailed insight was gained into how phase separation, elemental diffusion, and fluid flow contribute to the development of complex BCC–FCC microstructures.

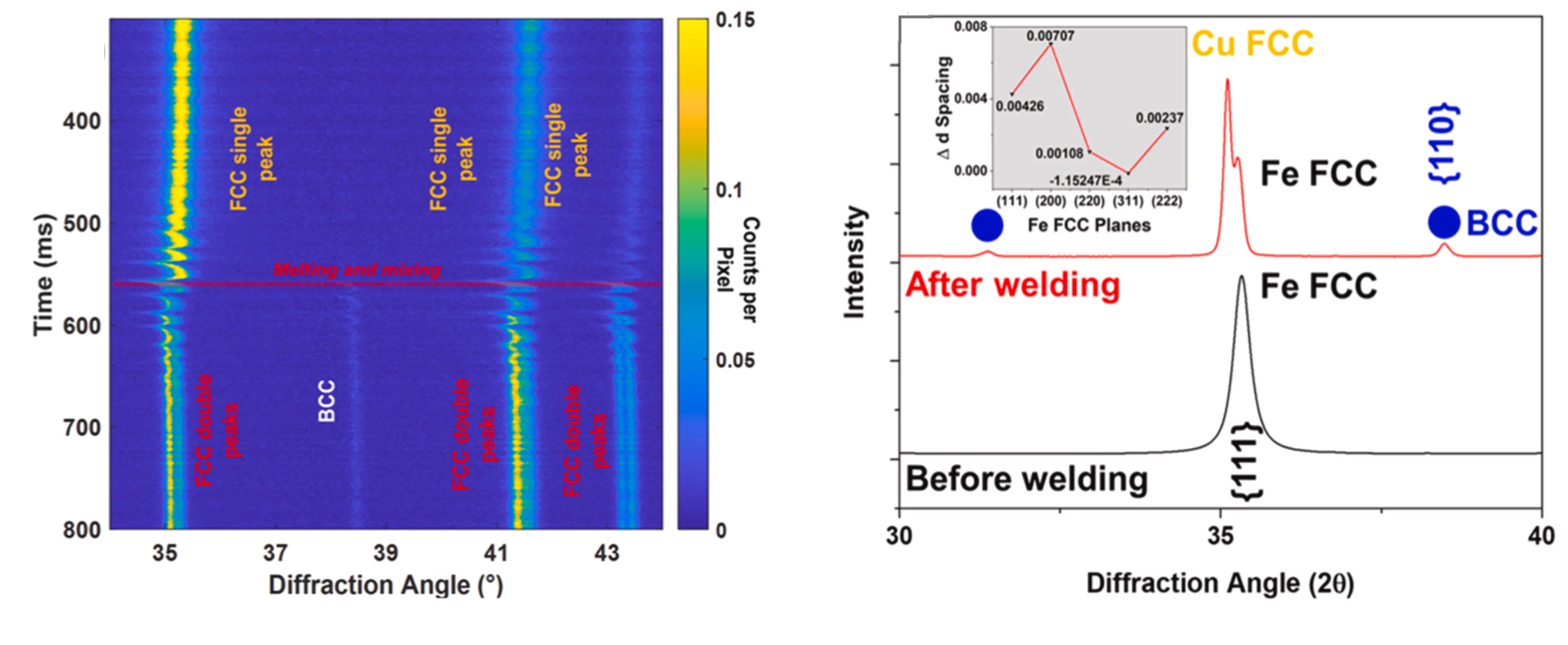

In-situ synchrotron X-ray diffraction (XRD) measurements, performed through a collaboration between EPFL and the Paul Scherrer Institute (PSI) at the Swiss Light Source, captured the real-time evolution of phases during laser processing. These observations, supported by advanced electron microscopy and thermodynamic modeling, revealed that the BCC phase forms via liquid-phase separation driven by the Fe–Cu miscibility gap. Marangoni convection and rapid solidification further shape the final microstructure, leading to composite-like regions where Fe-rich BCC phases coexist with Cu-rich FCC phases.

This work demonstrates how processing strategies can be tuned to control microstructure formation in multi-material metal additive manufacturing.

Contact

Dr. Steven Van Petegem

Structure and Mechanics of Advanced Materials, Center for Photon Science

Paul Scherrer Institute, Forschungsstrasse 111, 5232 Villigen PSI, Switzerland

Telephone: +41 56 310 2537, e-mail: steven.vanpetegem@psi.ch

Original publication

Formation Mechanism and Microstructural Characteristics of a Body-Centered Cubic Phase in 3D Printed 316L–CuCrZr Multi-Material Structures, Combining Laser Powder Bed Fusion with Foils

A. M. Jamili, I. Basu, C. Cayron, S. Van Petegem, J. Jhabvala, A. Nicholas Grundy, D. Weisz-Patrault, J. Nohava, A. Ozsoy, N. Casati, J. F. Löffler, R. E. Logé

Scripta Materialia 268, 116844 (2025)

DOI: 10.1016/j.scriptamat.2025.116844