How do materials withstand the world’s most intense radiation environments? At the Swiss Spallation Neutron Source SINQ, the STIP program provides unique insight into how metals and ceramics degrade under high-energy proton bombardment.

Facility: SINQ (Swiss Spallation Neutron Source)

Established: 1998

Focus: Proton irradiation of materials

Duration per experiment: ~7 years

Key outputs: Irradiated samples, helium and hydrogen data, mechanical property changes

Applications: Spallation, ADS, fusion, fission materials R&D

Overview of the STIP programme

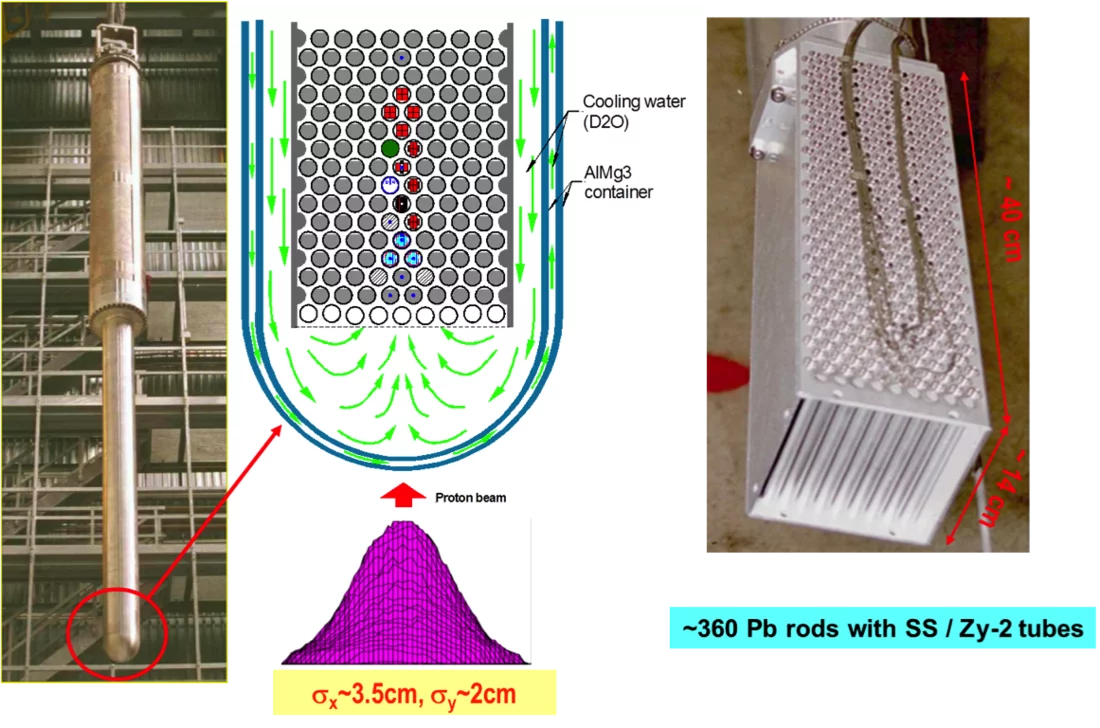

STIP is conducted at SINQ, the Swiss Spallation Neutron Source at PSI, which uses high-energy protons to generate an intense flux of neutrons. Unlike fission reactors, which produce mainly low-energy neutrons, STIP exposes materials to both the high-energy protons from the accelerator and the broad spectrum of spallation neutrons generated in the target.

This unique combination makes it possible to study multiple degradation mechanisms simultaneously, such as displacement damage, helium and hydrogen accumulation, and, where relevant, liquid metal corrosion. The combined damage caused by these different effects is greater than each acting alone, so-called ‘synergistic effects,’ such as helium and hydrogen enhanced embrittlement and irradiation assisted stress corrosion cracking.

For irradiation, small material samples, called specimens, are encapsulated in metal rods designed to fit into the target assembly. The design allows these specimen rods to be positioned directly in the high-flux region of a SINQ target. After the target has been operating for about two years, exceptionally high levels of damage and gas concentration are produced inside these specimens that cannot be achieved in fission reactors.

The materials to be irradiated – provided primarily by research institutes and industrial partners – include structural alloys (based on iron, nickel, aluminium, zirconium and molybdenum), ceramics such as silicon carbide, and functional metals like tungsten and tantalum. These are used in applications ranging from spallation sources and accelerator-driven systems (ADS) to fusion and fission research projects.

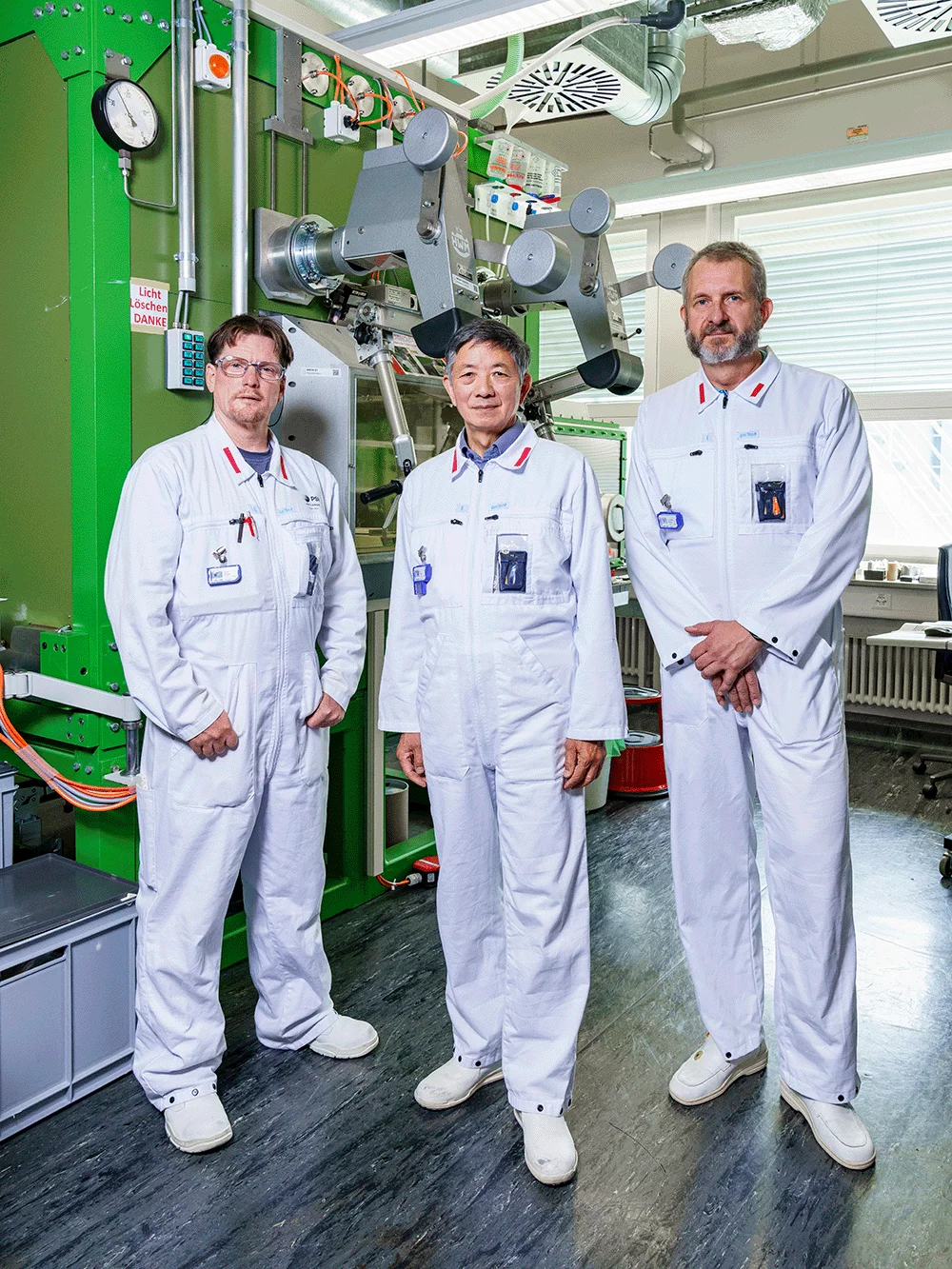

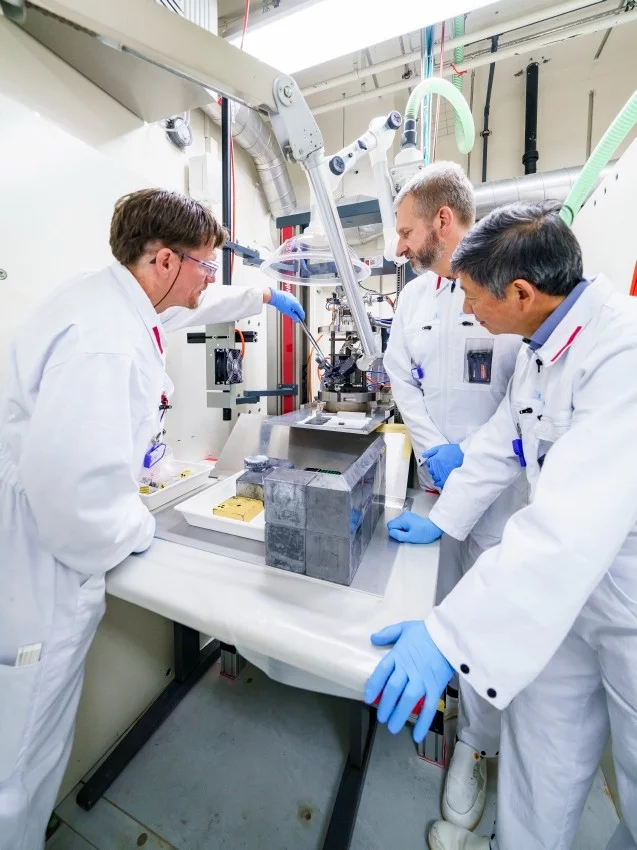

STIP has been led for nearly three decades by Dr. Yong Dai of PSI’s Laboratory for Nuclear Materials (LNM). While STIP is coordinated by the Spallation Materials Technology team at LNM, its success depends on the support of many other PSI groups, including Hotlab, the SINQ target operation group, ATEC, SU, the Electron Microscope Facility, and the ETH Zurich-based ScopeM.

Scientific motivation and context

When PSI’s Günter Bauer proposed the SINQ Target Irradiation Program (STIP) in 1996, little was known about how materials behave under the harsh irradiation conditions inside high-power spallation targets.

Since its launch in 1998, STIP has become a globally unique and indispensable resource for understanding radiation damage in materials and supporting the development of safe, long-lived components for nuclear installations.

The main purposes of STIP are:

- to provide necessary materials data for developing advanced spallation targets;

- to understand radiation, He and H effects in different structural materials;

- to study liquid metal effects on structural materials in intensive irradiation environments.

Experimental methodology

Each STIP experiment is a complex, multi-year endeavour that unfolds over four distinct phases: a planning phase, the irradiation itself, an initial evaluation of the specimens, and finally the post-irradiation examination. These four phases span at least seven years.

Phase 1: Planning

Planning a STIP campaign involves evaluating proposals, receiving and preparing materials to be irradiated, designing and fabricating the specimen rods, and preparing them for insertion into the SINQ target. This phase also requires extensive computer-based neutronic and thermohydraulic simulations to ensure that specimens receive the intended irradiation dose and temperature.

Phase 2: Irradiation

The irradiation itself lasts about two years, during which the temperature data from selected rods are continuously recorded by the SINQ target group. After the target has been operating for about two years, the specimens have experienced exceptionally high levels of damage.

Phase 3: Extraction and initial evaluation of the specimens

Following irradiation, the target is left for a period to allow short-lived radioactive isotopes to decay, reducing the radiation levels of both the target and the test samples. Then specimen rods are extracted from the spent target in the hot cell facility (ATEC) located near the SINQ target station. The rods are then transferred to PSI’s Hotlab, where they are opened, cleaned, identified, and categorised based on their residual radioactivity in preparation for post-irradiation examination.

In parallel to the work at the Hotlab, the proton beam profile during the irradiation is reconstructed by performing a detailed gamma mapping of the target window, which separates the accelerator vacuum from the target. This mapping, involving 1,681 individual measurements, provides the data needed to determine the proton fluence distribution across the target and accurately calculate the irradiation dose received by each specimen.

Phase 4: Post-irradiation examination (PIE)

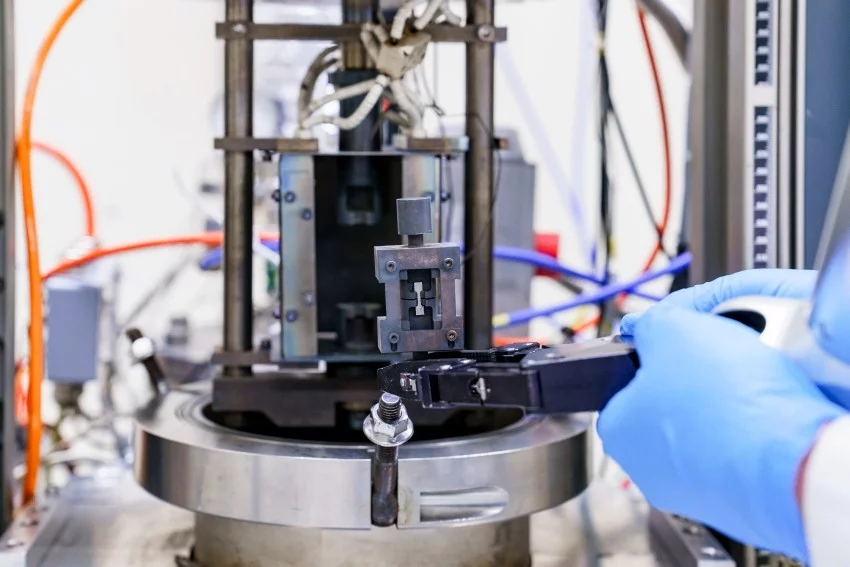

The Post-Irradiation Examination can take many years to complete, depending on the number of specimens and the complexity of the analyses. The specimens are subjected to a wide range of mechanical and microstructural characterisations, including tensile and impact tests, hardness measurements, and nanoindentation. Advanced techniques such as Transmission and Scanning Electron Microscopy and Atom Probe Tomography are used to reveal microstructural changes at micro- and atomic scale, helping researchers understand the mechanisms behind material degradation.

From initial planning and specimen preparation to irradiation, safe extraction, and post-irradiation examination, each STIP campaign spans many years and requires close coordination between PSI teams and international partners, yielding unmatched data on material performance under extreme conditions and shaping the future of safer, longer-lasting nuclear technologies worldwide.

Key findings and scientific impact

The SINQ Target Irradiation Program stands as a globally unique platform for materials testing under extreme conditions. With its ability to generate high-dose irradiation combined with helium and hydrogen production in the irradiated material, STIP makes it possible to study degradation processes relevant to both existing and next-generation nuclear systems. Its results continue to inform the design and safe operation of spallation sources and fusion reactors around the world.

One of the most significant findings of the programme is that helium concentration in the material, rather than displacement damage alone, often determines the operational lifetime of components. Today, helium concentration is a key design criterion for critical components such as proton beam windows.

Recovery of exotic radionuclides

Beyond their role in materials testing, STIP samples have also become a unique source for producing rare and scientifically valuable radionuclides. After post-irradiation examination, carefully selected specimens have been processed at PSI to recover long-lived isotopes such as 44Ti, 53Mn, 60Fe, 129I, 36Cl, and rare-earth α-emitters like 148Gd and 154Dy. These radionuclides, generated under extreme irradiation in the SINQ target, cannot be produced in comparable quality or quantity elsewhere.

Through advanced radiochemical separations, followed by high-purity sample preparation via techniques such as molecular plating, well-characterised targets have been produced for Accelerator Mass Spectrometry and high-precision half-life measurements. The resulting data provide critical benchmarks for nuclear astrophysics, nuclear reaction modelling, and safety assessments of next-generation spallation sources, where accurate knowledge of activation products is essential.

This recovery programme significantly broadens the impact of STIP, linking applied materials research with fundamental nuclear physics and radionuclide metrology. In doing so, it turns highly irradiated samples into a resource that continues to generate scientific value long after the original irradiation campaign.

Facilities and technical capabilities

STIP stands as a globally unique platform for materials testing under extreme conditions. The irradiation dose can reach about 15 dpa (in Fe) per year, accompanied with high production rate of helium (~1000 appm/y) and hydrogen (~5000 appm/y). More than 9000 samples from 80+ different materials of Fe-, Al-, Ti- Ni-, Mo- & W-alloys and ceramics (C/SiC, SiC/SiC…) were irradiated in the eight experiments (STIP-1 to -8) up to 30 dpa / 2000 appm He (in steels) at temperatures up to ~600°C.

International collaboration and users

Since the early 2000s, research institutions and universities across Europe, the USA, Japan, and China have relied on STIP. STIP data have been used by other major spallation sources (such as the Spallation Neutron Source at Oak Ridge National Laboratory in the US, the European Spallation Source in Sweden, the Japan Spallation Neutron Source, and the China Spallation Neutron Source) to evaluate target performance and predict component lifetimes. STIP results have formed the backbone of material studies presented at the recurring International Workshop on Spallation Materials Technology series and have featured in numerous invited talks at the International Conference on Fusion Reactor Materials.

Outlook: future vision for STIP

In alignment with the goals of STIP, the continuation of the classical STIP program is under consideration. This could lead to significant advancements in materials research. A new irradiation station is envisaged, which would enhance the capabilities of the existing program. This new station is foreseen to incorporate flexible instrumentation, allowing for a wide range of experimental setups tailored to specific research needs. By integrating additional features into the STIP framework, the program will continue to serve as a pivotal resource for understanding material behaviour under extreme conditions, thereby supporting the ongoing evolution of nuclear systems.

The new station will be strategically located in an area with a less hard neutron spectrum, which is essential for optimizing experimental conditions and minimizing unwanted radiation effects. This setup will facilitate in situ experiments, enabling real-time observation of material behaviour under irradiation. Such experiments are of highest interest to the fusion and fission community, as they will provide valuable insights into material degradation and performance, ultimately contributing to the development of safer and more efficient nuclear technologies.

Publications

-

Cui L, Li J, Gerstl S, Pouchon M, Dai Y

Quantitative APT analysis of solid transmutants in ferritic-martensitic steels after irradiation in SINQ targets: experimental validation of neutronic calculations

Nuclear Instruments and Methods in Physics Research, Section B: Beam Interactions with Materials and Atoms. 2021; 502: 1-9. https://doi.org/10.1016/j.nimb.2021.05.017

DORA PSI -

Dai Y, Odette GR, Yamamoto T

The effects of helium in irradiated structural alloys

In: Konings RJM, Stoller RE, eds. Comprehensive nuclear materials. Amsterdam: Elsevier; 2020:186-234. https://doi.org/10.1016/B978-0-12-803581-8.12046-6

DORA PSI -

Dai Y, Bauer GS

Status of the first SINQ irradiation experiment, STIP-I

Journal of Nuclear Materials. 2001; 296(1-3): 43-53. https://doi.org/10.1016/S0022-3115(01)00544-X

DORA PSI