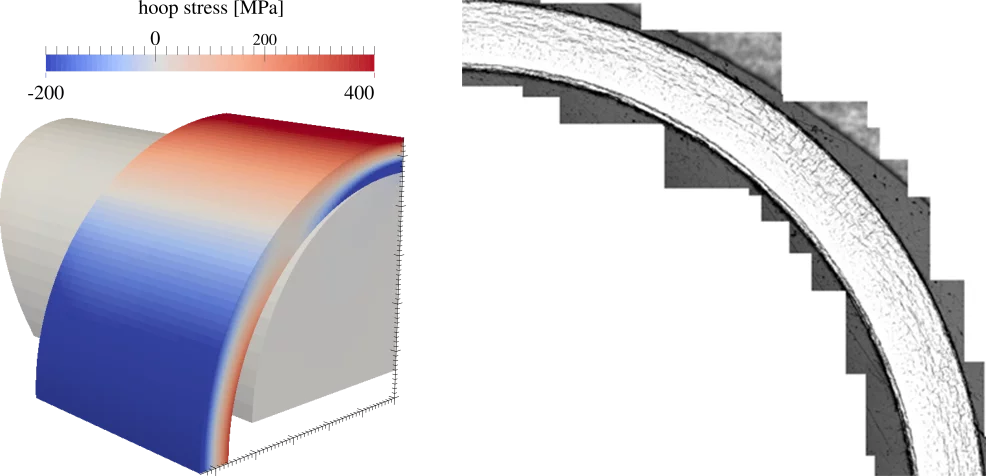

Once hydrogen has diffused into the cladding, it influences the mechanical properties. Hydrogen in solution can enhance the creep rate of the cladding at high temperature. A concentration above the hydrogen solution limit leads to precipitation into hydrides. The hydrides are brittle and reduce the ductility of the material. If hydrides are oriented in the unfavorable radial direction of the cladding, the tendency to brittle failure can be enhanced. The distribution/location, length and orientation of each individual hydride on a 360° cross section of a fuel rod and related statistical information can be obtained with the PSI image analysis software HYDIVA. The hydrides distribution and morphology can closely be linked with the prevailing stress conditions.

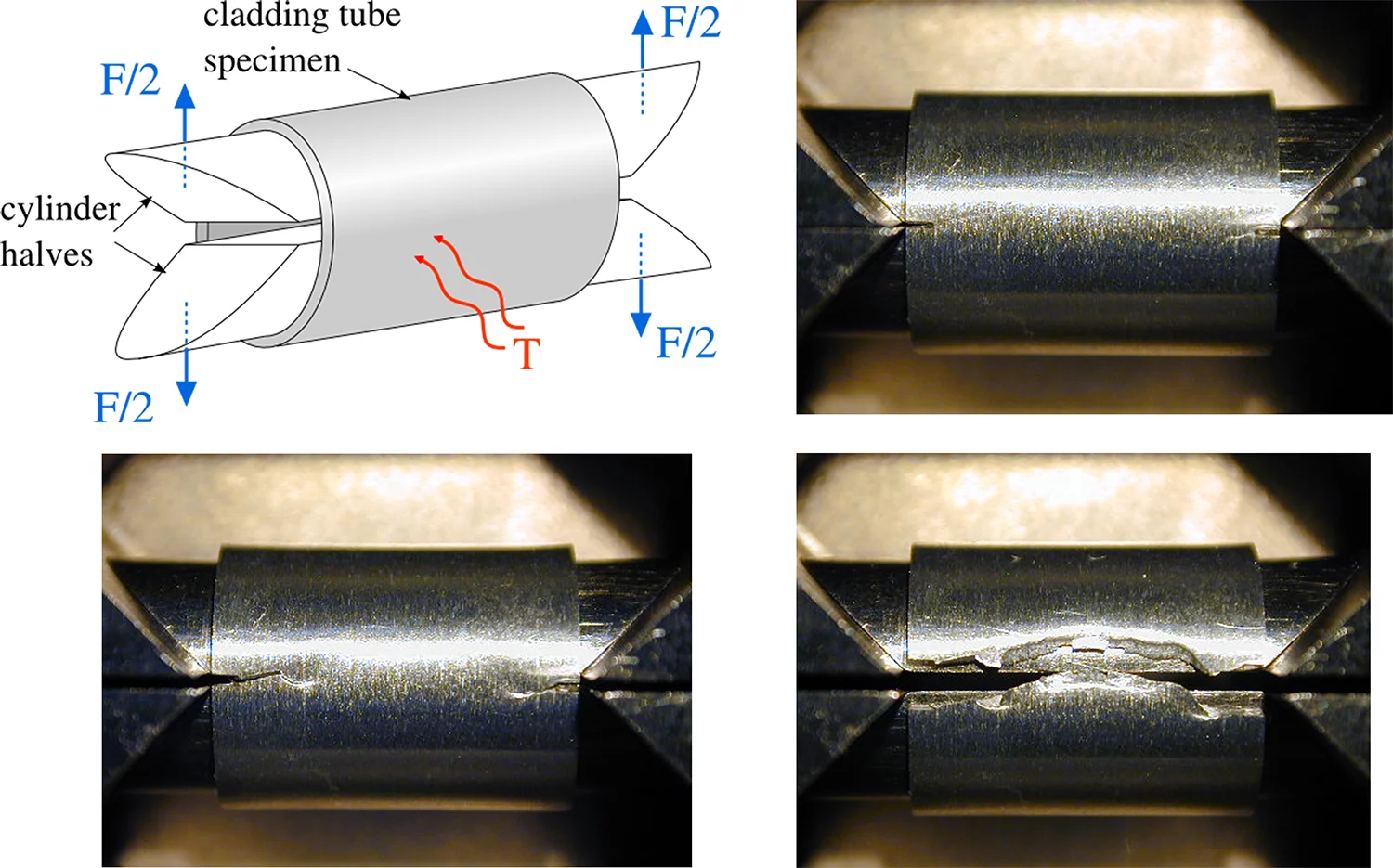

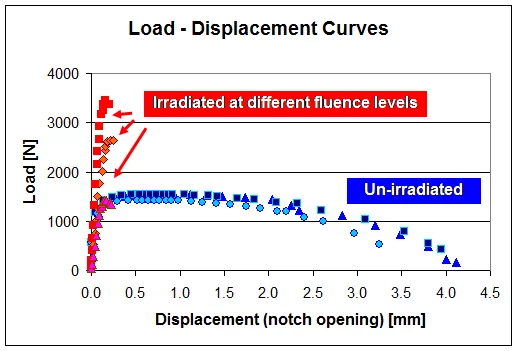

Another hydrogen effect is the so-called Delayed Hydride Cracking (DHC) where hydrogen diffuses to stress raisers (e.g. scratches, small cracks), precipitates in the stress field, fails and extends a crack. All these phenomena are investigated with thermo-mechanical testing (hydrides re-orientation, DHC), hydrogenation and diffusion experiments, accompanied by modelling of stress fields in the non-standard samples and by modelling of hydrogen diffusion and precipitation.