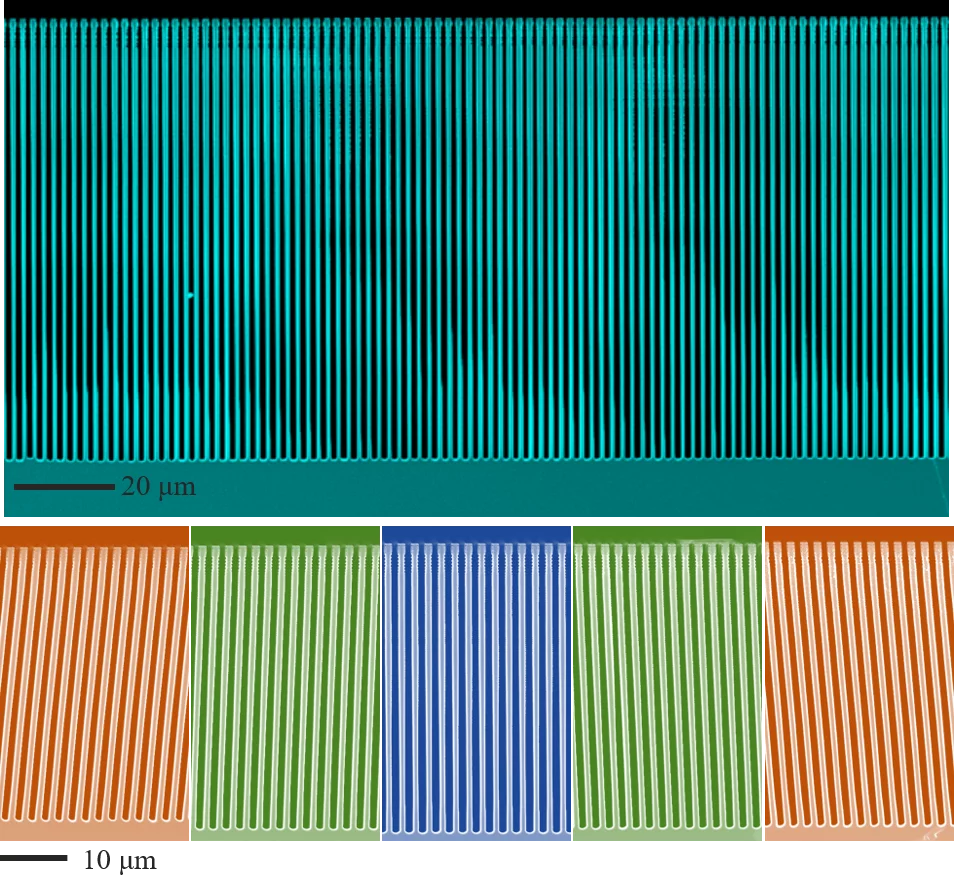

In X-ray grating interferometry (XGI) setups, silicon based gratings are usually adapted as interferometry pattern generators, and could serve as beam splitters and fringe analyzers after the trenches of the gratings are filled with high absorption materials. For the purpose of improving the sensitivity of phase contrast and dark field imaging, XGI system designers ask for gratings with periods in the micrometer or even sub micrometer range. High aspect ratio gratings are indispensable for high X-ray energy applications. Besides, alignment between X-rays and grating lines is necessary for compact designs. The grating fabrication team has developed a mature process flow of grating fabrication, and is now pushing the limits of the fabrication technology with new designs and processing for improved gratings performance [1-7]. One of the most robust way to fabricate silicon gratings with good uniformity over wafer scale (up to 8 inch available in clean room of PSI) is plasma etching by deep reaction ion etching methods [3]. We keep pushing the aspect ratio to the higher level. A unique tilted etching method has been developed in order to make absorption gratings that have fan-shaped grating line distributions for the purpose of improving the beam alignment [5] without mechanical bending. A demonstrative setup equipped with a fan-shaped source grating showed an increased field of view and an improvement of visibility at the edge area [6].

Publications

- Shi, Z., Jefimovs, K., Romano, L. & Stampanoni, M. Optimization of displacement Talbot lithography for fabrication of uniform high aspect ratio gratings. Japanese Journal of Applied Physics 60, SCCA01 (2021).

- Vila-Comamala, J. et al. High sensitivity X-ray phase contrast imaging by laboratory grating-based interferometry at high Talbot order geometry. Opt. Express 29, 2049-2064, doi:10.1364/OE.414174 (2021).

- Shi, Z., Jefimovs, K., Romano, L. & Stampanoni, M. Towards the Fabrication of High-Aspect-Ratio Silicon Gratings by Deep Reactive Ion Etching. Micromachines 11, 864 (2020).

- Josell, D. et al. Pushing the Limits of Bottom-Up Gold Filling for X-ray Grating Interferometry. Journal of The Electrochemical Society 167, 132504 (2020).

- Shi, Z., Jefimovs, K., La Magna, A., Stampanoni, M., & Romano, L. High aspect ratio tilted gratings through local electric field modulation in plasma etching. Applied Surface Science, 152938 (2022).

- Shi, Z., Jefimovs, K., Romano, L., Vila-Comamala, J., & Stampanoni, M. Laboratory X-ray interferometry imaging with a fan-shaped source grating. Optics Letters, 46(15), 3693-3696 (2021).

- Shi, Z., Josell, D., Jefimovs, K., Romano, L., Moffat, T.P., Stampanoni, M., & Schlepütz, C.M. Fabrication of a Fractal Pattern Device for Focus Characterizations of X-ray Imaging Systems by Si Deep Reactive Ion Etching and Bottom-up Au Electroplating. Applied Optics, 61, 3850-3854 (2022).

Collaboration

- Dr. Martin Stauber, GratXray, PARK innovAARE, 5234 Villigen, Switzerland