PSI has a unique (worldwide) environment for the investigation of highly radioactive / toxic materials:

> Materials (different fuel types including ATF, very high burnup, various cladding materials, materials activated in SINQ)

> The hot lab with advanced tools for analysis and preparation of micro-specimen

> The large scale facilities for advanced material investigations

This unique combination on the PSI campus, allows to enables us to meet the needs of our industrial partners (Swiss power plants, fuel vendors, Research partners) for improving safety / efficiency in plants up to basic research.

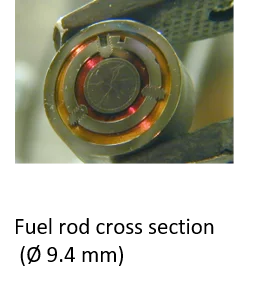

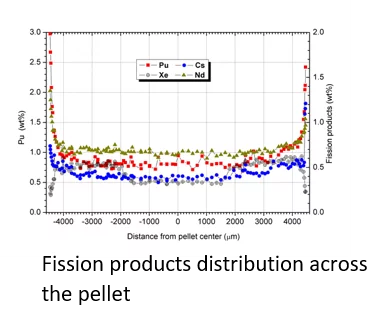

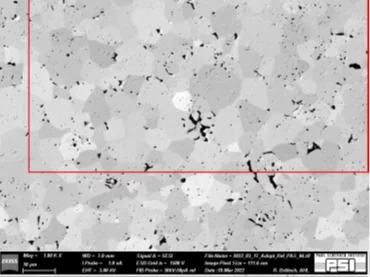

One of the various analytical tools in the AHL is the shielded electron probe microanalyzer (EPMA), which is used to determine the quantitative (wt%) fission product distribution (Fig.2) across the cross-section of a pellet (Fig.1) for verification analysis of material behavior and validation of models.

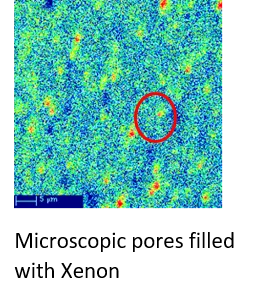

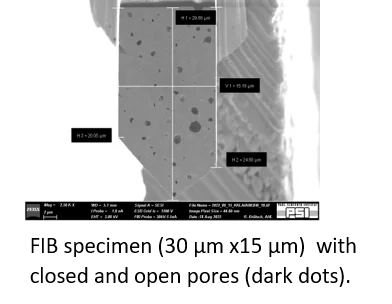

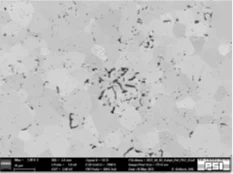

The Xe behavior during transients/failures (LOCA, RIA) is an important safety parameter (bursting of the cladding due to overpressure) (Fig.3) and cannot be measured at the periphery with EPMA (open pores) (Fig.5). On the other hand, Xe is a neutron absorber, which has a negative effect on the efficiency of the fuel.

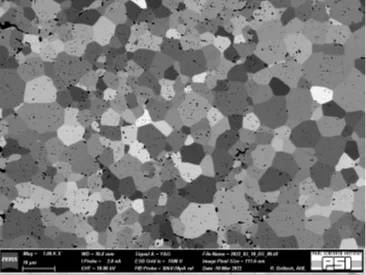

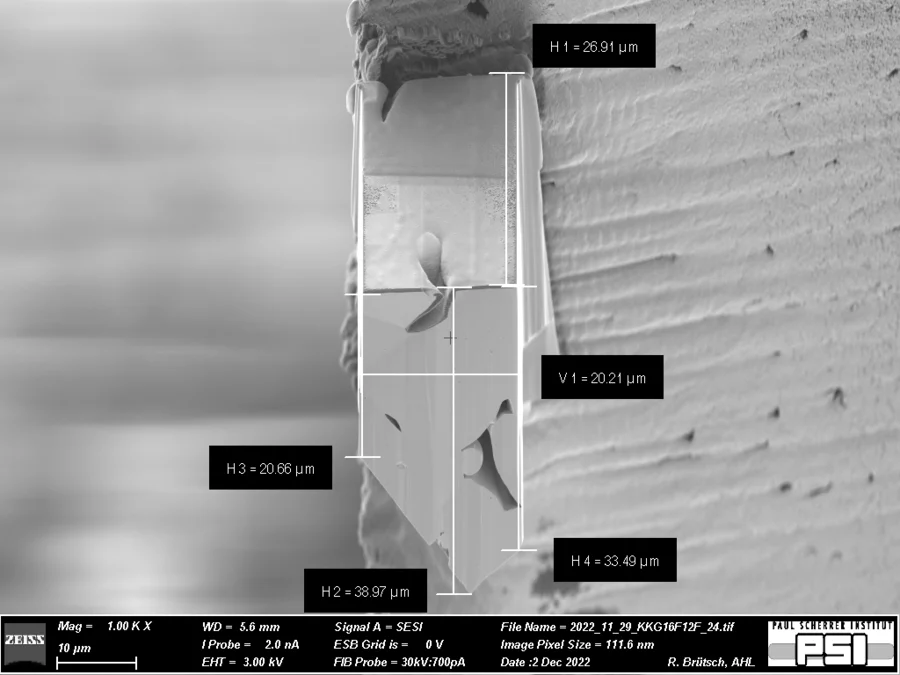

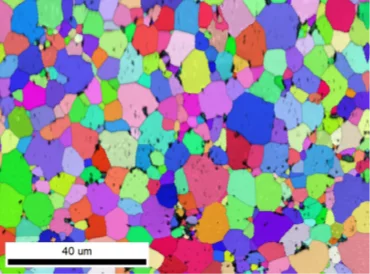

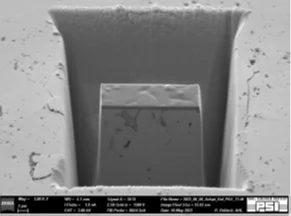

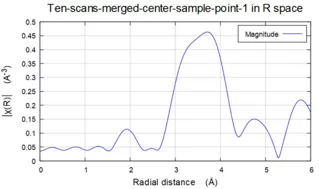

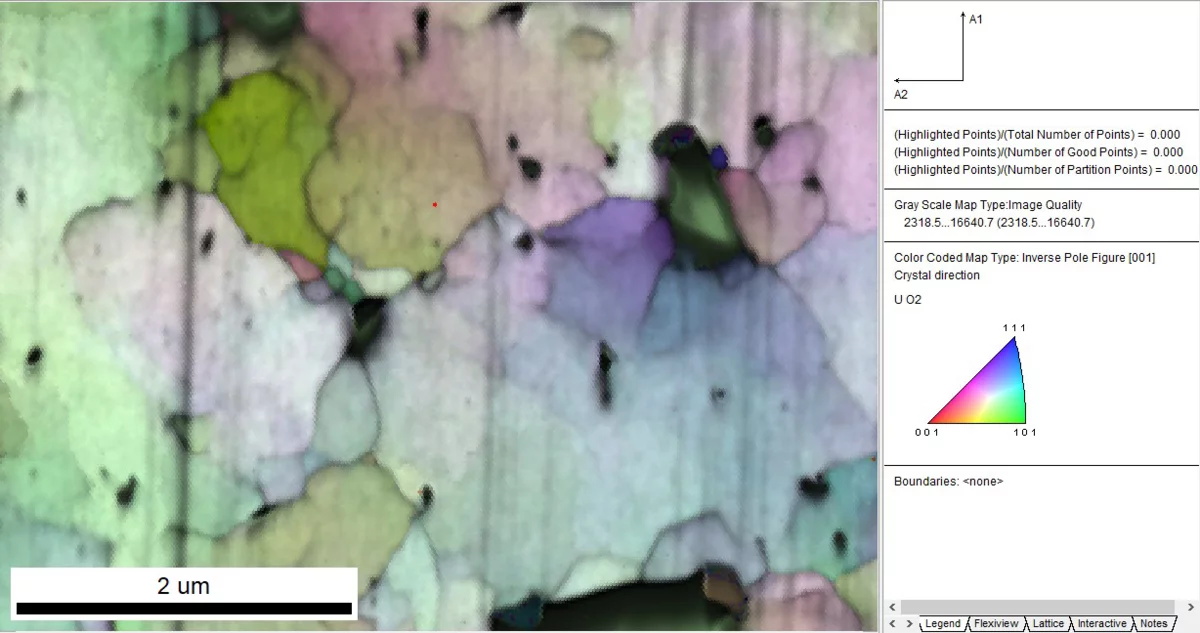

FIB X-ray mapping on the fuel sample cross-section is used to locate where a thin micro-sample (Fig.10, Fig.4) is taken for detailed analyses. Secondary Electron (SE), Back Scattered Electron (BSE), Energy-Dispersive X-ray Spectrometry (EDS), and Electron Backscattered Diffraction (EBSD) analyses (Fig.9, Fig.12) in the micro-sample optimize the locations for a more detailed investigation of Xe behavior (Fig3) on the microXAS beamline (Fig.4).

Using the same specimen (Fig.5) at the microXAS beamline more detailed analysis for Xe behavior and effect on the formation of the porosity / microstructure (Fig.6) can be studied. The same micro-sample (Fig.7) can be used to perform synchrotron light-based micro-beam X-ray diffraction (μXRD) and X-ray absorption spectroscopy (μXAS) on the microXAS beamline (Fig.11).

Taking into account the previous ENSI requirements and the implementation of those for FIB system approval, the tests shown above were successfully carried out as commissioning tests. After the final ENSI approval, the FIB system will allow the preparation of micro-samples and their analysis of different irradiated materials at specific locations (interfaces, anomalies, phases, ...) in the micrometer range.

Since these micro-samples have a very small volume (about 10-12 cm3) (Fig.7) and therefore have almost no activity/toxicity, they can be transported and analyzed in the large facilities for very detailed analyses.

Authors

Matthias Martin

matthias.martin@psi.ch

phone: +41 56 310 4179

Head of Analytic Radioaktive Materials, Hotlaboratory

Roland Brütsch

roland.bruetsch@psi.ch

Analytic Radioaktive Materials, Hotlaboratory

Dr. Johannes Bertsch

johannes.bertsch@psi.ch

Nuklear Fuels, Nuclear Materials

Dr. Goutam Kuri

goutam.kuri@psi.ch

Nuklear Fuels, Nuclear Materials