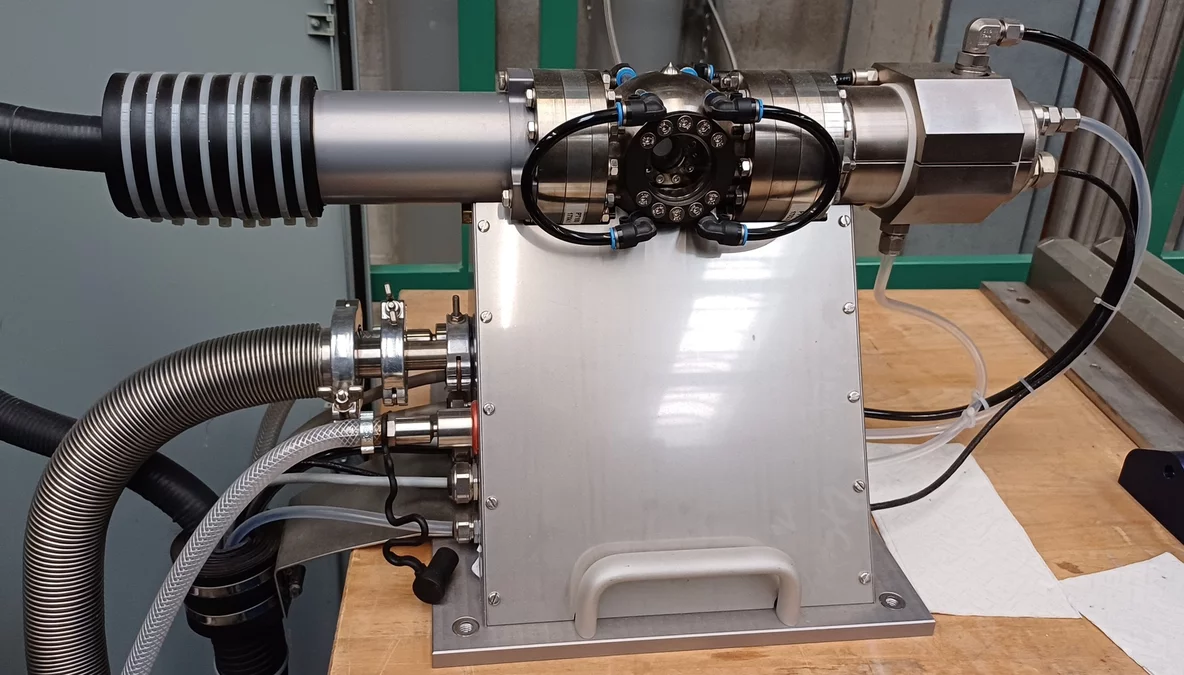

Climate Chamber

Construction of a climate chamber (“Humidity chamber”) for SANS instruments. With this climate chamber, small material samples (e.g. foils with Ø20mm) can be specifically humidified (20% ... 95% RH) and tempered (50°C ... 100°C) at a controlled chamber pressure of 1070 mbar. FEM design for climate accuracy (±1 °C, ±2% RH), humidification homogeneity and rapid climate changes (time constants = 2 ... 7 minutes).

Designed by L. Holitzner

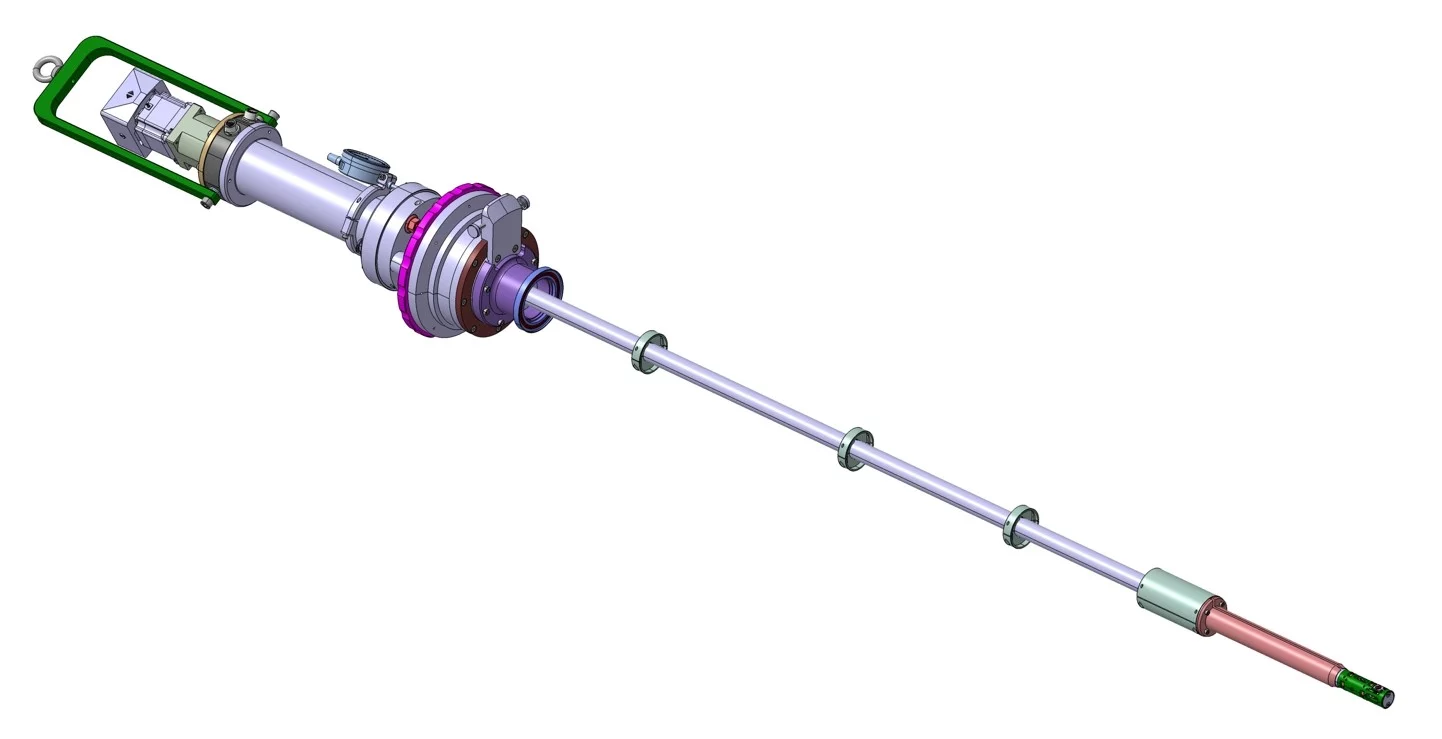

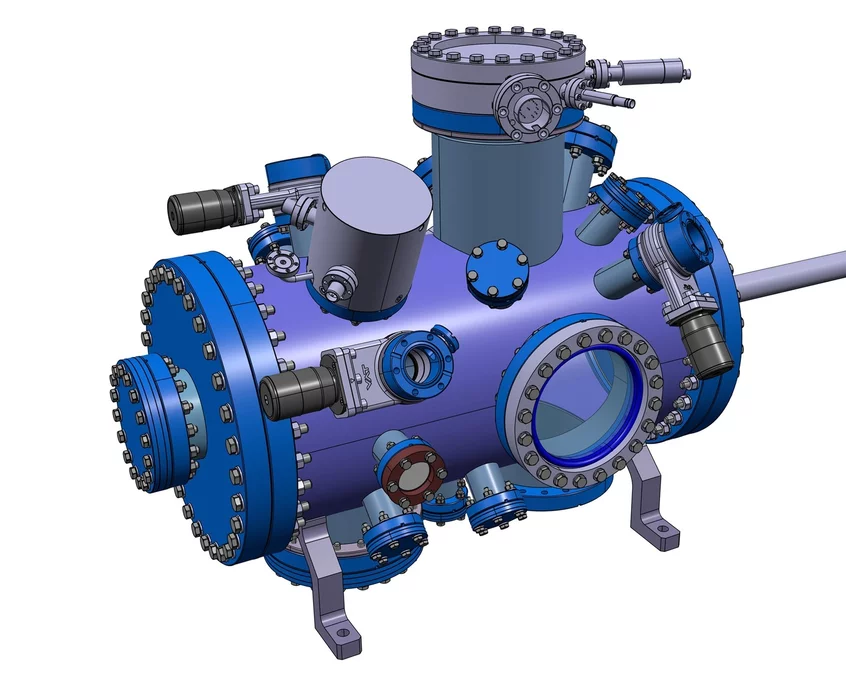

Vacuumchamber for LEM

For the Low-Energy Muon Facility (LEM), a vacuum chamber was developed that allows the handling of samples in an oxygen-free environment. A large number of feedthroughs, optical windows and an ion source were placed in the cylindrical body of the chamber.

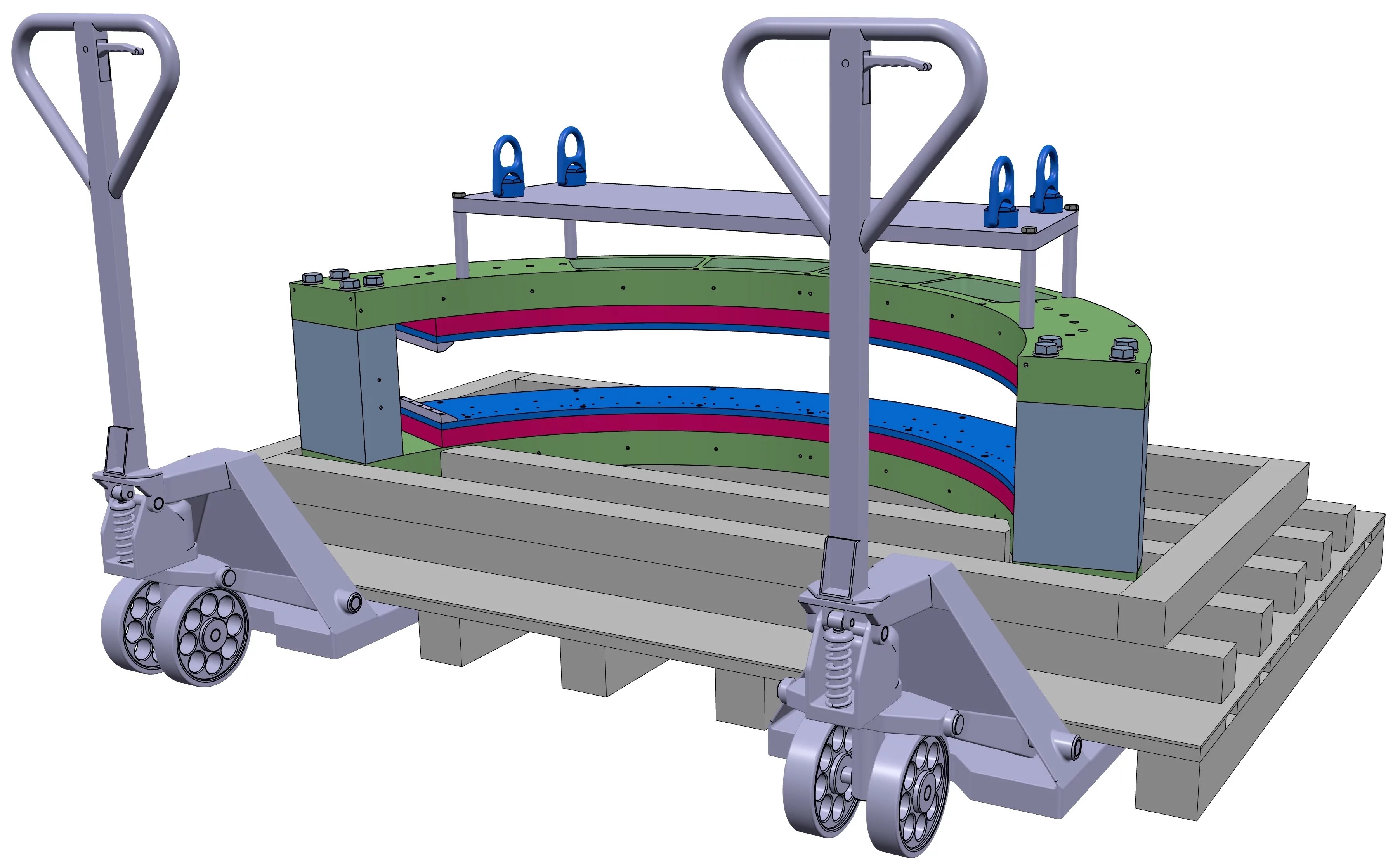

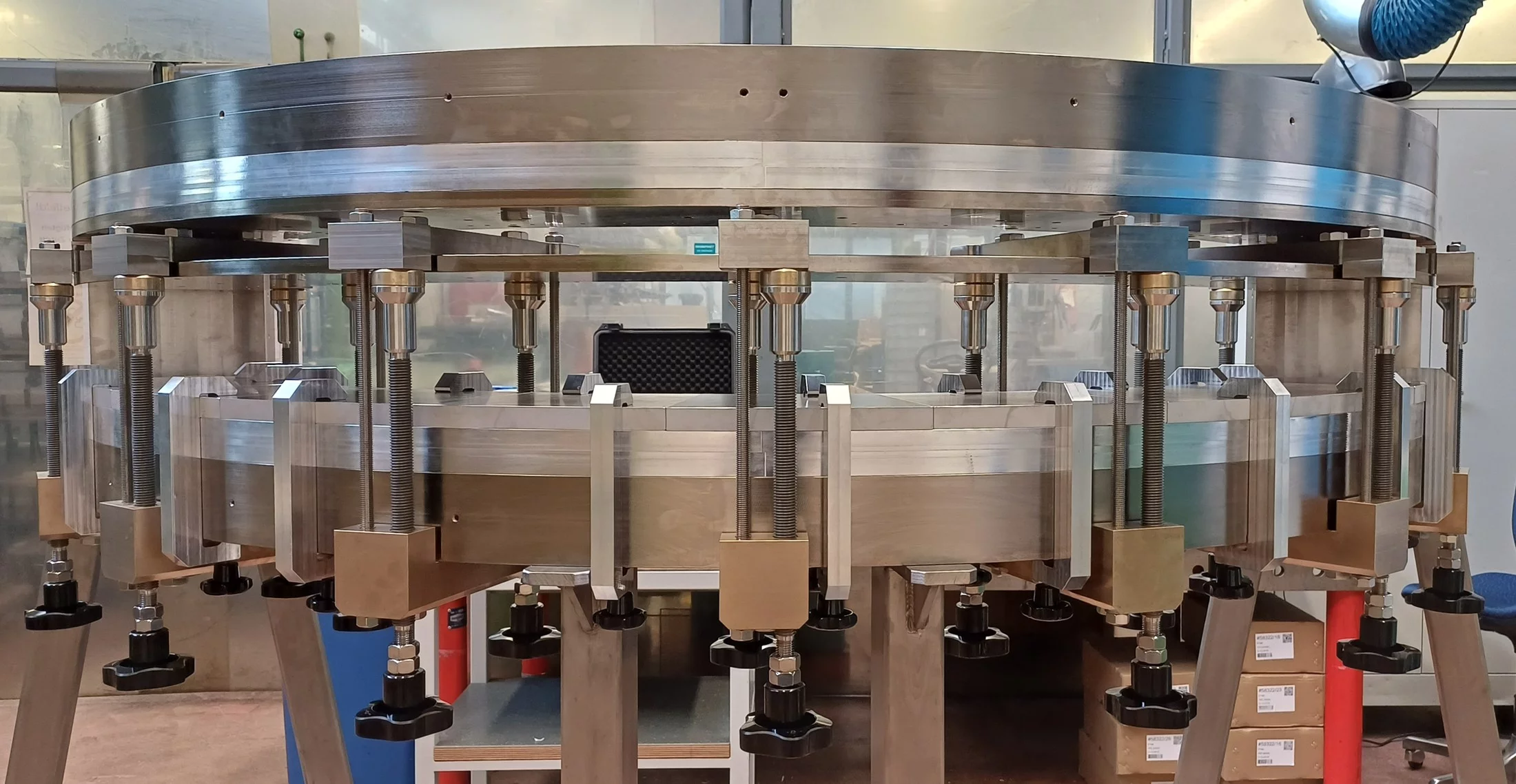

Magnetic field for MAGIC

MAGIC is a fully polarized single-crystal diffractometer, being built at ESS.

For this instrument a big magnetic field was designed and manufactured. The magnetic field contains more than 6300 permanent magnets and produces a magnetic field of 0.1 Tesla

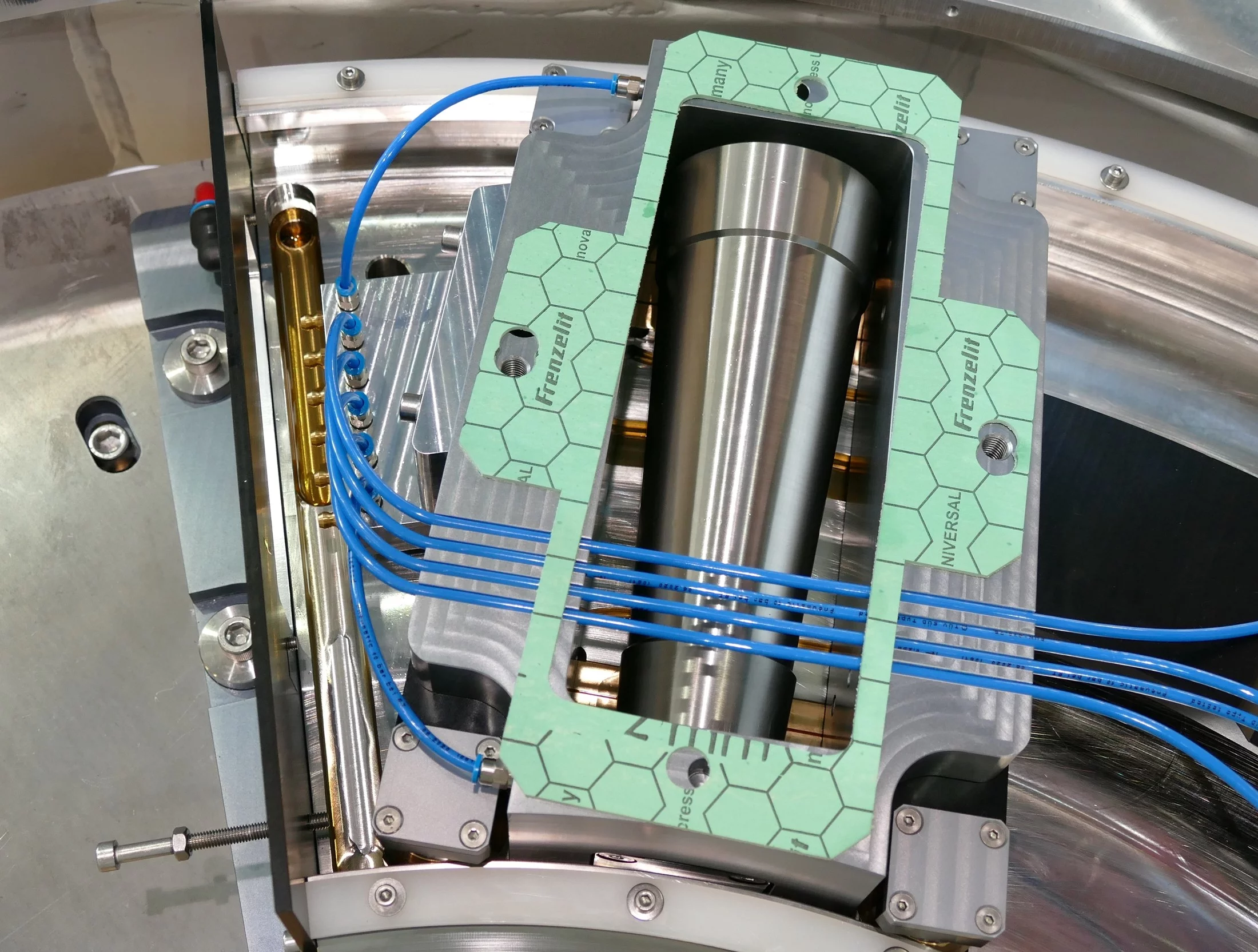

Oscillator unit for the DMC radial collimator

In the cold neutron diffractometer (DMC), a radial collimator is located in front of the instrument's detector. To improve the quality of the sample signal, the radial detector is moved continuously by +- 1.8°.

The challenge was to build a non-magnetic, curved device that can move the radial collimator precisely and is very durable.