The dominating conventional Zn recycling process is the so-called Waelz process: Waelz oxide, containing 70-75 % ZnO, is produced from electric arc furnace dust generated in large amounts during steel recycling. After its washing treatment to separate off chlorides, Waelz oxide is recycled together with primary ZnS concentrates for the production of Zn metal.

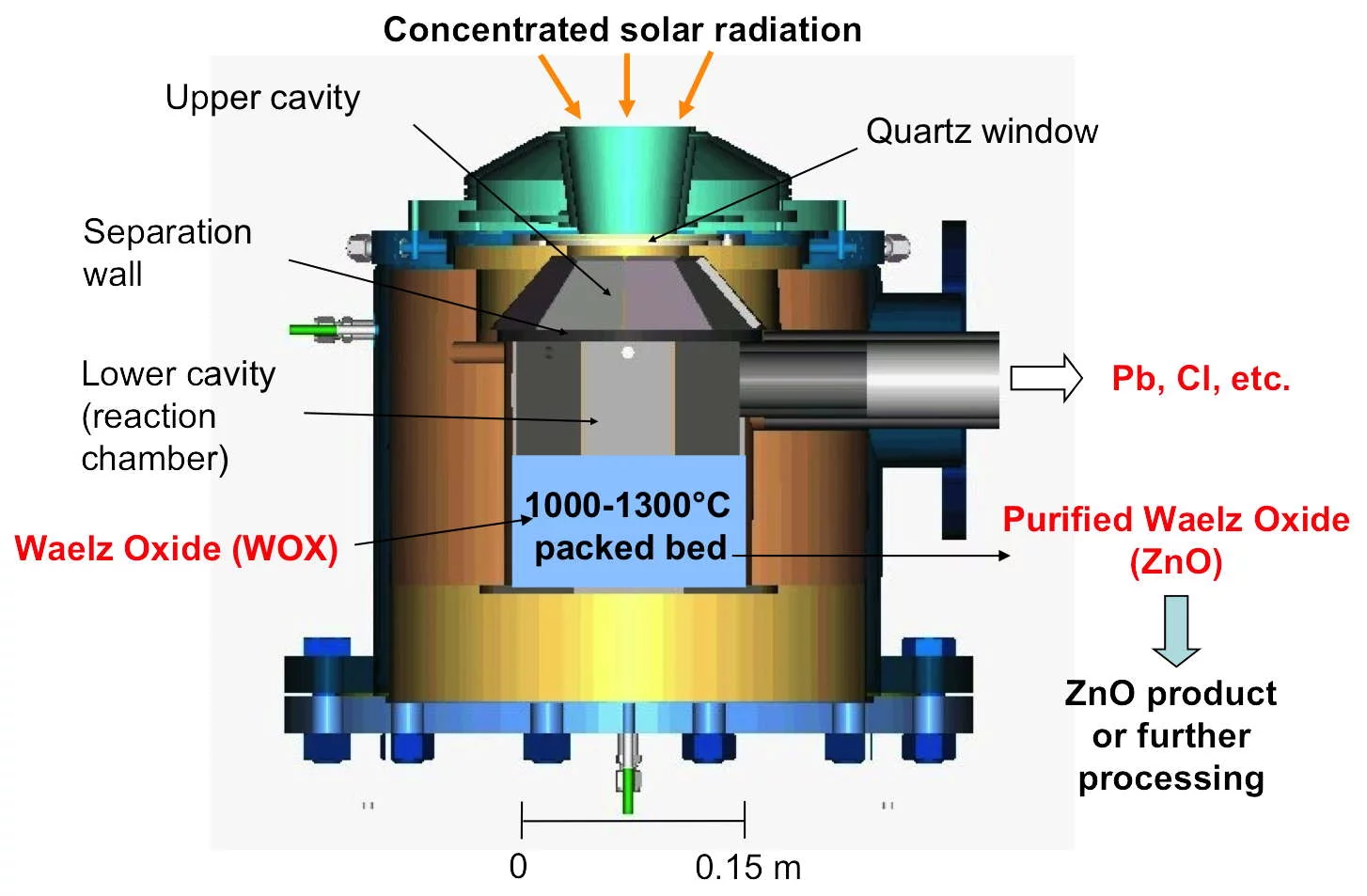

In the current project alternative process routes for the purification of Waelz oxide and for the production of Zn/ZnO using concentrated solar power to supply the required high-temperature process heat were explored. Experimentation was carried out at PSI’s High Flux Solar Simulator with a 5-10 kW packed bed two-cavity beam down solar reactor. Promising results were obtained for both processes investigated: the solar purification (“clinkering”) of Waelz oxide and the carbothermal reduction of crude, washed and solar purified Waelz oxide to produce mainly Zn and CO.

Presentation slides

In the current project alternative process routes for the purification of Waelz oxide and for the production of Zn/ZnO using concentrated solar power to supply the required high-temperature process heat were explored. Experimentation was carried out at PSI’s High Flux Solar Simulator with a 5-10 kW packed bed two-cavity beam down solar reactor. Promising results were obtained for both processes investigated: the solar purification (“clinkering”) of Waelz oxide and the carbothermal reduction of crude, washed and solar purified Waelz oxide to produce mainly Zn and CO.

Presentation slides

Citation: N. Tzouganatos, R. Matter, C. Wieckert, J. Antrekowitsch, M. Gamroth, A. Steinfeld, TMS-Journal of Metals, Vol. 65, Dec. 2013

Publication: DOI

Further publications: LST Publications

Publication: DOI

Further publications: LST Publications