Infrared imaging sheds new light on the condensation/evaporation process

Matter and Material Nuclear Power Plant Safety

Researcher at PSI (NES/LRT) have brought modern infrared technologies into their large thermal-hydraulic facility, called LINX, to obtain insights into condensation/evaporation process occurring under thermodynamic conditions resembling those of a nuclear power plant containment during a severe accident scenario. In such a scenario, condensation is of prime importance to control the thermodynamic state of the containment. It affects the pressure history, the overall gas (steam, hydrogen) and fission product distribution within this last barrier. Better understanding of these phenomena under accident conditions is essential to properly predict the accident evolution.

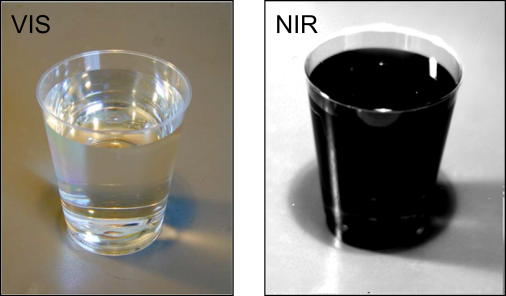

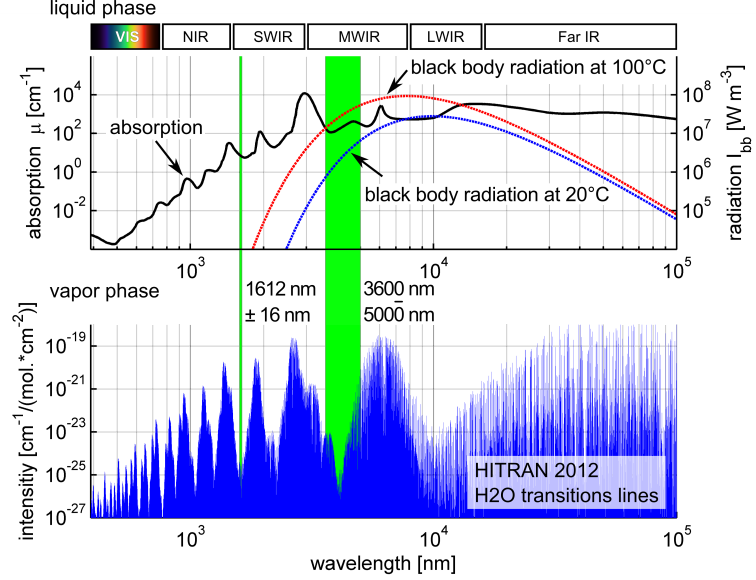

New applications of infrared imaging were developed to simultaneously obtain both thickness and surface temperature of a falling water film. If one could see with eyes sensitive to infrared light, the world would look rather dark (Header Image). Thankfully, our eyes can enjoy the colour of the visible spectrum; technology, however, can give us more. Both techniques use the infrared properties of water in liquid and vapour phase. They are designed to see through steam (low absorption band depicted in green in Figure 1. The film thickness measurement is an attenuation technique for which light is shone onto the film, reflecting on the wall surface and measured with a near infrared camera through a narrow band filter centred at 1612 nm. The film surface temperature measurement is a more standard thermography method that measured the emission of the thin upper layer (~50 µm) of the film. Great efforts were put into the calibration performed live and in-situ.

The techniques were then implemented in the LINX facility. Containment-like condition could be recreated in the main vessel (10 m3) while a two metre high temperature controlled wall act as test section for the falling film observation. Test campaign was conducted with high steam content and pressure up to 2.5 bar. Measurements were obtained with spatial resolution of 0.6 mm and a minimum sampling rate of 125 Hz. An accuracy of 20 µm and less than 90 mK were inferred for the film thickness and temperature, respectively.

A clear correlation between the fluctuating part of the film thickness and the fluctuating part of the film surface temperature was observed. The movie below shows that temperatures are cooler at the crest of the rolling waves than at the through inferring that evaporation process is enhanced at the crest. Similar correlation was observed for condensation as well but to a lower extent. The data obtained in the LINX project open a door to new validation and analytical work associated with the film dynamics in presence of heat and mass transfer. Further development and implementation of the technique in presence of aerosol are currently on-going.