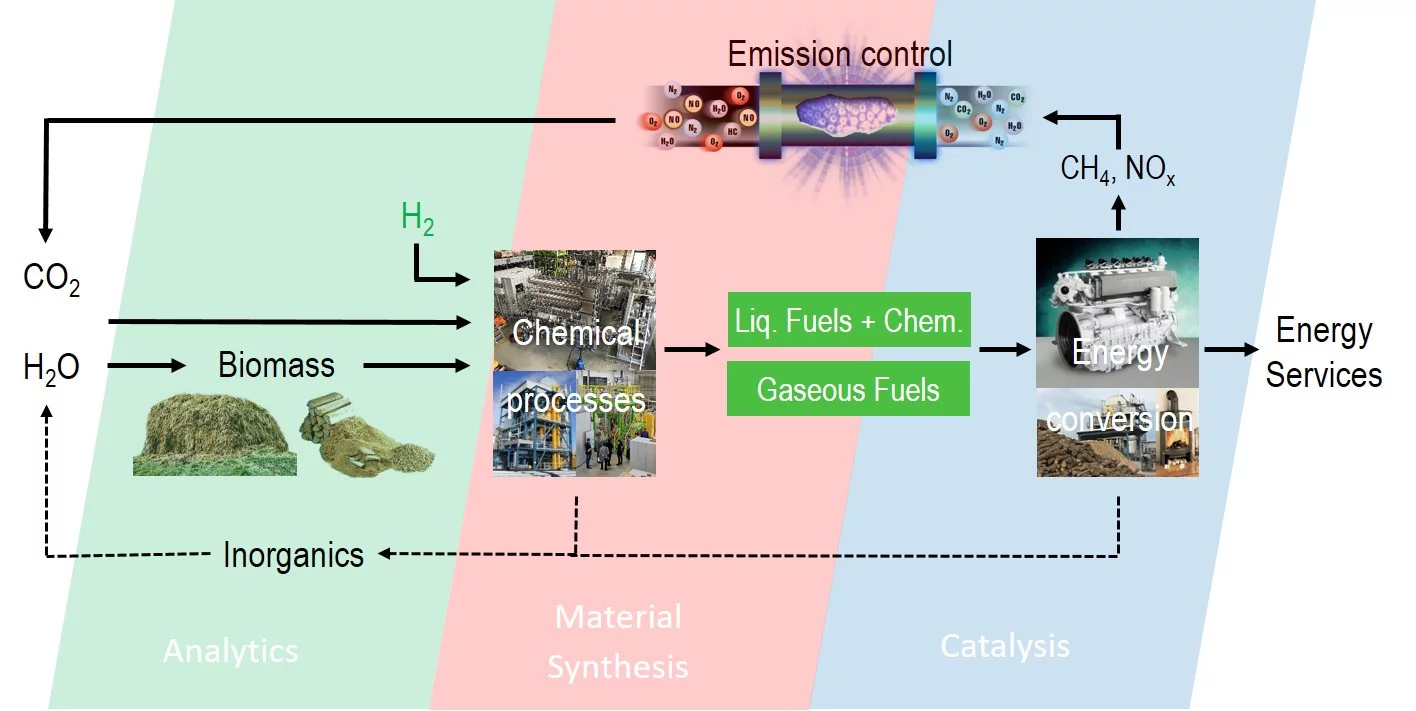

The Laboratory for Sustainable Energy Carriers and Processes (LEP) is developing thermochemical processes for the production of gaseous and liquid energy carriers from CO2, biomass and/or waste. The conversion of energy carriers into energy services is associated with various emissions that have to be reduced to minimize the environmental impact of energy supply and use in our society. This also involves the recycling of inorganics contained in biomass, the used catalysts and materials as well as the different process streams. The development of sustainable processes requires a comprehensive understanding of the ongoing chemistry and physicochemical phenomena, which LEP studies from the atomistic level in the laboratory to the production level in the field. LEP uses catalysis, advanced spectroscopy and chemical engineering as key competences for the development of sustainable processes.

The head of the LEP, Oliver Kröcher, is adjunct professor at the EPFL, where he leads the Group for Sustainable Energy Carriers (GSE), working on complementary research topics.

Energy carriers from wet biomass

With the catalytic hydrothermal gasification, developed in the Catalytic Process Engineering (CPE) group, wet biomass resources can be processed efficiently to renewable methane as gaseous energy carrier. The upscaled technology is being transferred to the market by the spin-off company TreaTech. Due to the extremely tight boundary conditions for an economically feasible process for renewable methane production from biomass, hydrothermal processes to liquid energy carriers and chemicals are increasingly researched and developed in the laboratory.

The head of the CPE group, Frédéric Vogel, is full professor at the Institute of Bioenergy and Resource Efficiency (IBRE), a joint institute of FHNW and PSI. He manages his research groups at PSI and FHNW as a single unit.

Conversion of renewable gas for energetic use

The Thermochemical Processes (TCP) group has developed a proprietary fluidized-bed technology for the conversion of syngas as well as CO2 from biogas or point sources to renewable methane, which excels by increased heat-transfer and space-time-yields, less catalyst deactivation due to coking, and lower CAPEX compared to the classical fixed-bed methanation or biological methanation, respectively. The technology is ready for transfer to industry, what is currently being done in collaboration with PSI’s spin-off company AlphaSYNT. LEP’s methanation technology has been succesfully integrated into different Power-to-Gas (PtG) concepts. This comprises the conversion of the CO2 in biogas to renewable methane and the flexible operation of biogas plants in summer and winter times using membrane gas upgrading. The group is currently focused on using their fluidized-bed technology for the production of liquid energy carriers, such as methanol.

Catalysts for energy conversion processes and clean exhaust gases

The development and investigation of advanced materials, particularly catalysts, is considered as the key for the further progress in the field. Therefore, the Applied Catalysis and Spectroscopy (ACS) group is working on catalysis for emission control and the production of energy carrier as well as on understanding reaction mechanisms using spectroscopy/diffraction under reaction conditions.

Material cycles and efficient use of resources

The development of new energy conversion processes in our laboratories is only reasonable when all material cycles are closed and if recycling and eco-efficiency are considered in all our R&D activities. These aspects are covered by the Chemical Processes and Materials (CPM) group.

The head of the CPM group, Christian Ludwig, is adjunct professor at the EPFL, where he leads another research group on complementary research topics.