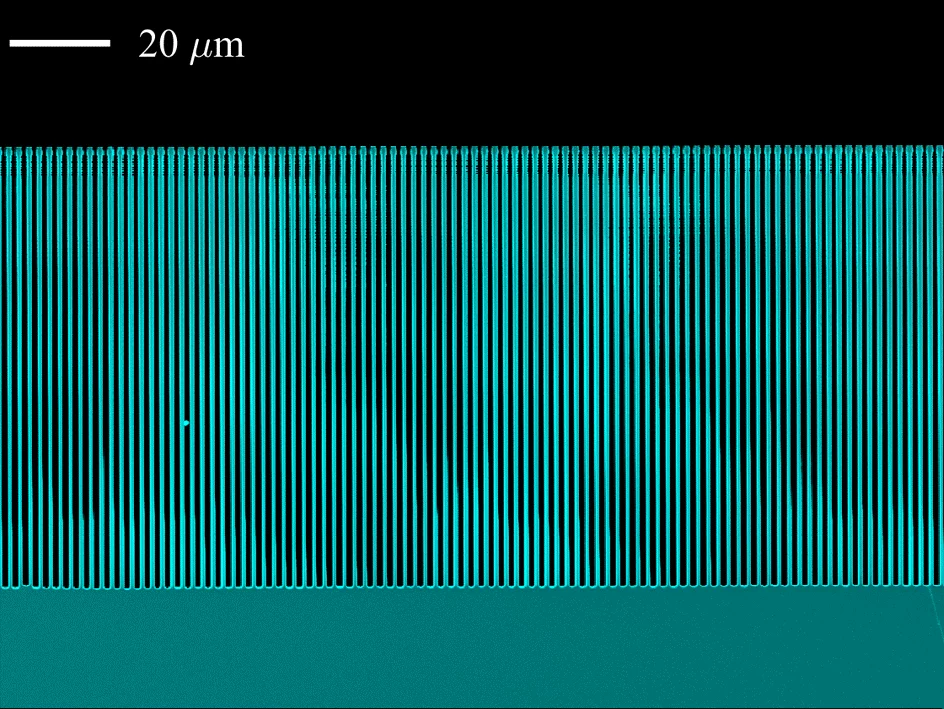

In X-ray grating interferometry (XGI) setups, silicon gratings are usually adapted as interferometry pattern generators, and could serve as beam splitters and fringe analyzers. The trenches of the gratings are filled with high absorption materials. For the purpose of improving the sensitivity of phase contrast and dark field imaging, XGI system designers ask for gratings with periods in the micrometer range. Large grating height is indispensable for high X-ray energy applications. In a word, the fabrication of gratings with high aspect ratios has become one of the key factors affecting the development of XGI. The grating fabrication team at TOMCAT has developed a mature process flow of grating fabrication, and is now pushing the limits of the fabrication technology with new designs and processing for improved gratings performance [1-4]. We also bring the most advanced nano- and micro- processing technologies into the lab to overcome obstacles on the road to high quality gratings. For example, displacement Talbot lithography was introduced to have uniformly patterned grating lines over wafer scale. Absorption gratings without voids and delamination defects are prepared in collaboration with GratXray (PSI spin off), EPFL and NIST.

References

- Jefimovs, Konstantins, et al. "High-aspect ratio silicon structures by displacement Talbot lithography and Bosch etching." Advances in Patterning Materials and Processes XXXIV. Vol. 10146. International Society for Optics and Photonics, 2017.

- Romano, Lucia, and Marco Stampanoni. "Microfabrication of X-Ray Optics by Metal Assisted Chemical Etching: A Review." Micromachines 11.6 (2020): 589.

- Kagias M, Wang Z, Guzenko VA, David C, Stampanoni M, Jefimovs K, "Fabrication of gratings by conformal seedless electroplating of gold on low resistivity silicon templates for X-ray interferometric imaging", Materials Science in Semiconductor Processing. 2019; 92: 73-79.

- Vila-Comamala J, Romano L, Guzenko V, Kagias M, Stampanoni M, Jefimovs K, "Towards sub-micrometer high aspect ratio X-ray gratings by atomic layer deposition of iridium." Microelectronic Engineering 192 (2018): 19-24.

Collaboration

- Dr. Martin Stauber, GratXray, PARK innovAARE, 5234 Villigen, Switzerland

- Dr. Daniel Josell, NIST, Gaithersburg, Maryland 20899, USA