The upgrade of the Swiss Light Source (SLS2.0) is one of the largest projects at PSI for the next years. It will significantly increase the performance of the SLS, while maintaining the current circumference of the electron storage ring of 288 meters. To meet these requirements, considerably more, much narrower and more sophisticated magnets are needed to keep the electrons on their orbit: In total, more than 1100 new customised magnets will be installed.

Between mid-April and the end of September 2022, members of the magnet section of the Accelerator Technology Department in the Large Research Facilities Division of PSI succeeded in measuring the first complete series of one type of magnet. These are 112 quadrupole electromagnets in four designs, which were conceived and constructed at PSI and built by the company SigmaPhi.

The quadrupoles were measured according to the principle of "rotating coils". This measurement system exploits the effect that a voltage is induced in a coil rotating in a magnetic field. A custom-made variant of the measurement system was developed at PSI in collaboration with Elettra Synchrotron Trieste specifically for the series measurement of the SLS2.0 magnets. It consists of five pick-up coils whose measurement signals, when rotated at the centre of the magnet, enable a precise analysis of the magnetic field.

The complex procedure for measuring the magnets includes, among other things, mechanically checking the magnet geometry, warming up the magnet to operating temperature overnight, measuring the operating temperature using a thermal imaging camera, determining the exact spatial position of the magnet on the measuring table, and measuring the magnetic field components at different currents and different positions of the magnet with a relative precision down to 500 ppm. This proceeding allows the magnets to be optimally adjusted later in the machine.

The first data evaluation showed that the quality of the delivered magnets can be considered good as well as the reliability of the measuring system as very high.

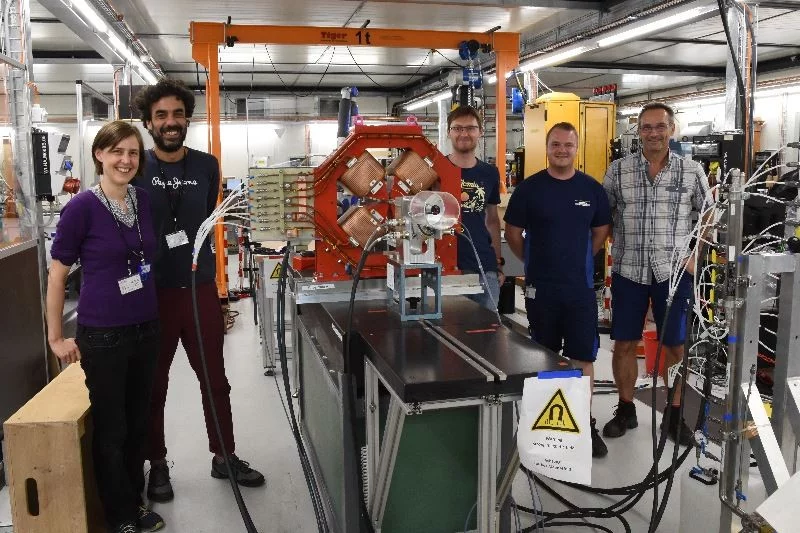

By optimising the measurement procedure, the three technicians and three engineers responsible for the measurements were able to achieve a measurement capacity of three magnets per day. Consequently, even faster completion of the measurements would have been possible if the manufacturer's delivery speed had not been limited. This gives hope for the big task of completely measuring the remaining approximately 1000 magnets by July 2024, and thus optimally meeting the schedule for SLS2.0.

Text: Paul Scherrer Institute / Carolin Zoller