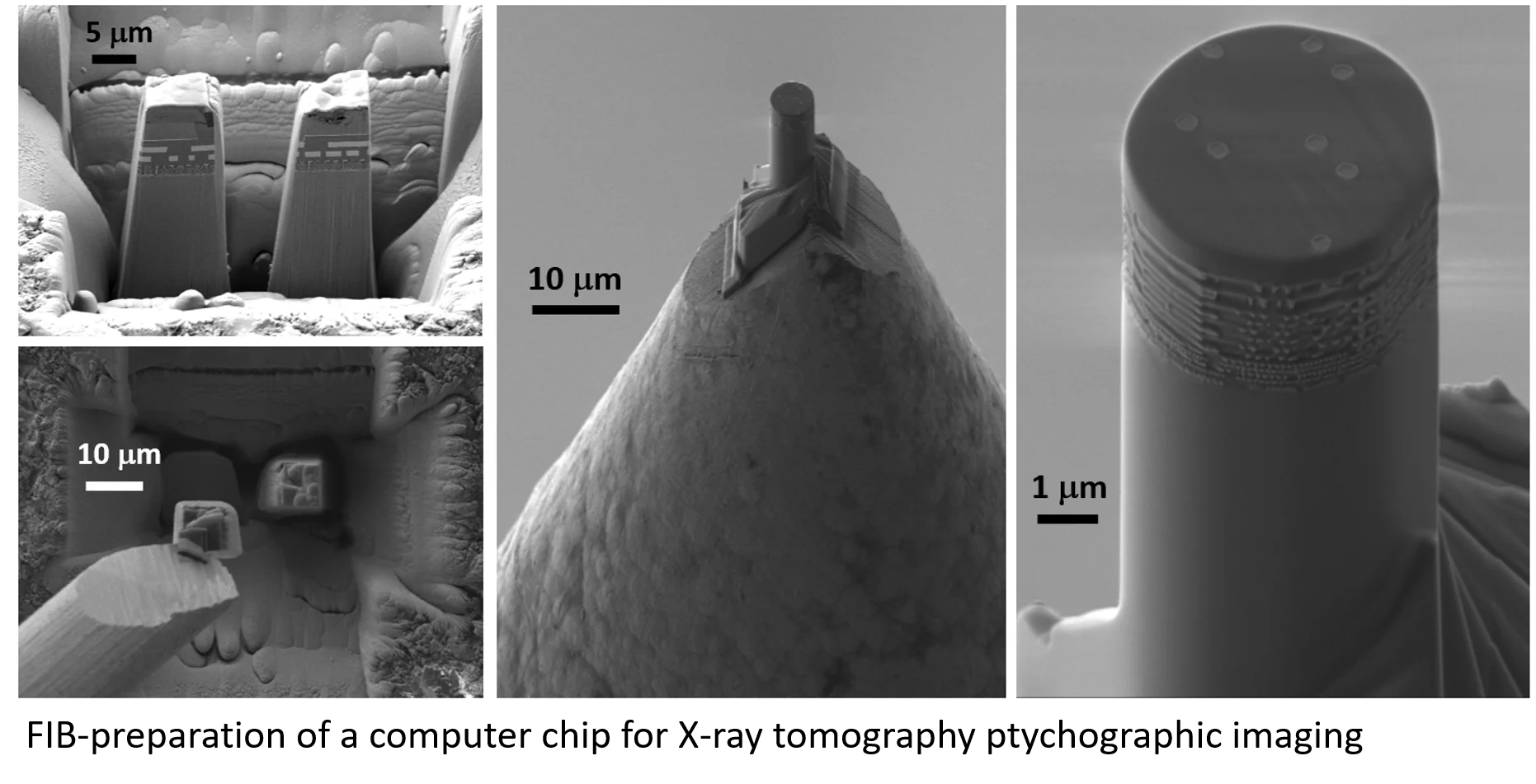

For tomographic X-ray imaging the specimen preparation is of high importance. It is often beneficial, if the sample has the shape of a small pillar, because the nearly constant specimen thickness along all imaging directions reduces the complexity for the calculation of the tomographic reconstruction. Additionally, the quality of the specimen has a direct influence onto the resolution which can be reached. Within the collaboration with our colleagues from the cSAXS beamline at the Swiss Light Source, we have prepared specimen from many different materials using our Ga-FIB/SEM. By now, a resolution of 15nm has been reached with Ptychographic X-ray Computed Tomography using hard X-rays.

- Three-dimensional imaging of integrated circuits with macro- to nanoscale zoom

Mirko Holler, Michal Odstrcil, Manuel Guizar-Sicairos, Maxime Lebugle, Elisabeth Müller, Simone Finizio, Gemma Tinti, Christian David, Joshua Zusman, Walter Unglaub, Oliver Bunk, Jörg Raabe , A. F. J. Levi and Gabriel Aeppli

Nature Electronics 464 (2019) 464–470 - High-resolution, Non-destructive X-ray Tomography

Mirko Holler, Manuel Guizar-Sicairos, Esther H. R. Tsai, Michal Odstrcil, Roberto Dinapoli, Elisabeth Müller, Ana Diaz, Oliver Bunk, Jörg Raab, and Gabriel Aeppli

CHIMIA 72 (2018) 339 - Resonant Ptychographic Tomography Facilitates Three-Dimensional Quantitative Colocalization of Catalyst Components and Chemical Elements

Johannes Ihli, Ana Diaz, Yuying Shu, Manuel Guizar-Sicairos, Mirko Holler, Klaus Wakonig, Michal Odstrcil, Teng Li, Frank Krumeich, Elisabeth Müller, Wu-Cheng Cheng, Jeroen Anton van Bokhoven, and Andreas Menzel

J. Phys. Chem. C 122 (2018) 22920−22929 - High-resolution non-destructive three-dimensional imaging of integrated circuits

M. Holler, M. Guizar-Sicairos, E.H.R. Tsai, R. Dinapoli, E. Müller, O. Bunk, J. Raabe, and G. Aeppli

Nature 543 (2017) 401-407 - Element-Specific X-Ray Phase Tomography of 3D Structures at the Nanoscale

C. Donnelly, M. Guizar-Sicairos, V. Scagnoli, M. Holler, T. Huthwelker, A. Menzel, I. Vartiainen, E. Müller, E. Kirk, S. gliga, J. Raabe, L.H. Heyderman

Phys. Rev. Lett.114 (2015) 115501

Research of the Photons for Engineering and Manufacturing (PEM) group, Center for Photon Science

The group of Photons for Engineering and Manufacturing is focused on characterization and description of mechanical and physical properties of materials with the aim to contribute in the area of advanced manufacturing. Combination of in-situ X-ray and neutron diffraction experiments supported by post-mortem characterization methods are widely used to achieve this goal. The group has developed mechanical deformation stages which enable to perform advanced in-situ experiments on beamlines of the Swiss Light Source (SLS), the POLDI beamline of the Swiss Spallation Neutron Source (SINQ) or in scanning electron microscopes (SEM). Furthermore, the group employs advanced analytical methods ranging from the macroscopic to the atomic level for better describing and understanding of the experimentally observed phenomena.

The group members perform various experiments and observations by electron microscopy in the Electron Microscope Facilities of the Laboratory of Biomolecular Research. SEM is extensively used for basic material characterization while Focus Ion Beam is a necessary tool for TEM sample preparation due to the small-scale specimens employed for in-situ diffraction measurements. As an advanced electron microscopy technique, TEM has an important supplementary and supportive role in materials characterization and clarification of the dislocations structure.

The most significant research project of the group is the ERC advanced grant funded project “MULTIAX” (MULTIAX-project) which deals with the behavior during multiaxial loading of metallic materials. The aim of the project is to shed light on the deformation mechanisms and create reliable models describing the mechanical behavior of materials upon multiaxial loading or strain path changes.

Publications of the group with electron microscopy within last 5 years:

- Deformation behavior of sintered nanocrystalline silver layers Zabihzadeh S, Van Petegem S, Duarte L I, Mokso R, Cervellino A, Van Swygenhoven H Acta Materialia 97, 116 (2015). DOI 10.1016/j.actamat.2015.06.040

- Dynamic recovery in nanocrystalline Ni Sun Z, Van Petegem S, Cervellino A, Durst K, Blum W, Van Swygenhoven H Acta Materialia 91, 91 (2015). DOI 10.1016/j.actamat.2015.03.033

- Picosecond pulsed laser for microscale sample preparation Guitton A, Irastorza-Landa A, Broennimann R, Grolimund D, Van Petegem S, Van Swygenhoven H Materials letters 160, 589 (2015) DOI 10.1016/j.matlet.2015.06.119

- On the origin of cementite diffraction peak broadening during tensile deformation at ambient temperatures Weisser M A, Van Petegem S, Cervellino A, Van Swygenhoven H International Journal of Plasticity 66, 138 (2015) DOI 10.1016/j.ijplas.2014.10.008

- Origin of Anomalous Slip in Tungsten Marichal C, Srivastava K, Weygand D, Van Petegem S, Grolimund D, Gumbsch P, Van Swygenhoven H Physical Review Letters 113, (2014) DOI 10.1103/PhysRevLett.113.025501

- {110} Slip with {112} slip traces in bcc Tungsten Marichal C, Van Swygenhoven H, Van Petegem S, Borca C Scientific Reports 3, Article number 2547 (2013) DOI 10.1038/srep02547

- Origin of localized rafting in Ni-based single crystal turbine blades before service and its influence on the mechanical properties Pierret S, Etter T, Evans A, Van Swygenhoven H Acta Materialia 61, 1478 (2013) DOI 10.1016/j.actamat.2012.11.024

- Slip in directionally solidified Mo-alloy micropillars - Part II: Pillars containing defects Zimmermann J, Van Swygenhoven H, Van Petegem S, Borca C Acta Materialia 60, 4614 (2012) DOI 10.1016/j.actamat.2012.02.042

- Slip in directionally solidified Mo-alloy micropillars - Part I: Nominally dislocation-free pillars Zimmermann J, Van Swygenhoven H, Marichal C, Van Petegem S, Borca C, Bartova B, Oveisi E, Hebert C Acta Materialia 60, 4604 (2012) DOI 10.1016/j.actamat.2012.02.043

- Effects of focused ion beam milling and pre-straining on the microstructure of directionally solidified molybdenum pillars: A Laue diffraction analysis Zimmermann J, Van Petegem S, Bei H, Grolimund D, George E P, Van Swygenhoven H Scripta Materialia 62, 746 (2010) DOI 10.1016/j.scriptamat.2010.02.013