Consistent criticality and radiation studies of Swiss spent nuclear fuel: The CS2M approach

Nuclear Power Plant Safety Matter and Material Particle Physics

The future of the spent nuclear fuel (SNF) is the focus of a large number of recent studies regarding intermediate and long-term storage. Three quantities are of prime importance considering the fuel itself: its long-lived radioactivity content (actinides and fission products), heat generation (also called decay heat) and radiation level (or source term). The high radiation level implies the use of shielding and remote handling systems, the heat generation limits the stored amount in a given volume of rock, and the radioactivity content means that the criticality safety of a repository can be an issue for the duration of the repository. Some of these quantities can also be measured (decay heat, radiation level), but systematic measurements on the thousands of SNF cannot be performed in practice (in Switzerland alone, about 12,000 fuel assemblies are expected to be finally discharged). Therefore the dependence on calculated quantities is capital. These three quantities are linked together as the isotopic content of a SNF is responsible for the produced decay heat, the emitted radiations and the possibility of criticality events: for instance, the correct knowledge of the amounts of 235U, 239Pu, 244Cm, and other isotopes is at the start of the correct assessment of the emitted number of neutrons, gammas, and of the criticality occurrence. In this work, we are proposing to calculate such isotopic content, decay heat, neutron & gamma sources and the neutron multiplication factor at once, taking into account the individual history of all fuel assemblies based on the LRT/STARS CMSYS platform containing reference validated plant- and cycle specific models for in-core reactor operation. Concretely, this coupling of CMSYS implies an enlargement of the methodology, hereinafter referred to as CS2M , to out-of-core spent fuel analyses involving four specific codes: CASMO and SIMULATE, SNF and MCNP. Thus, the CS2M calculation scheme consists of two specific couplings: 1) CMSYS with SNF to reconstruct isotopics and calculate their evolution during decay; 2) SNF to MCNP using the in-house COMPLINK methodology to initialize the material compositions of all fuel rods in the MCNP models.

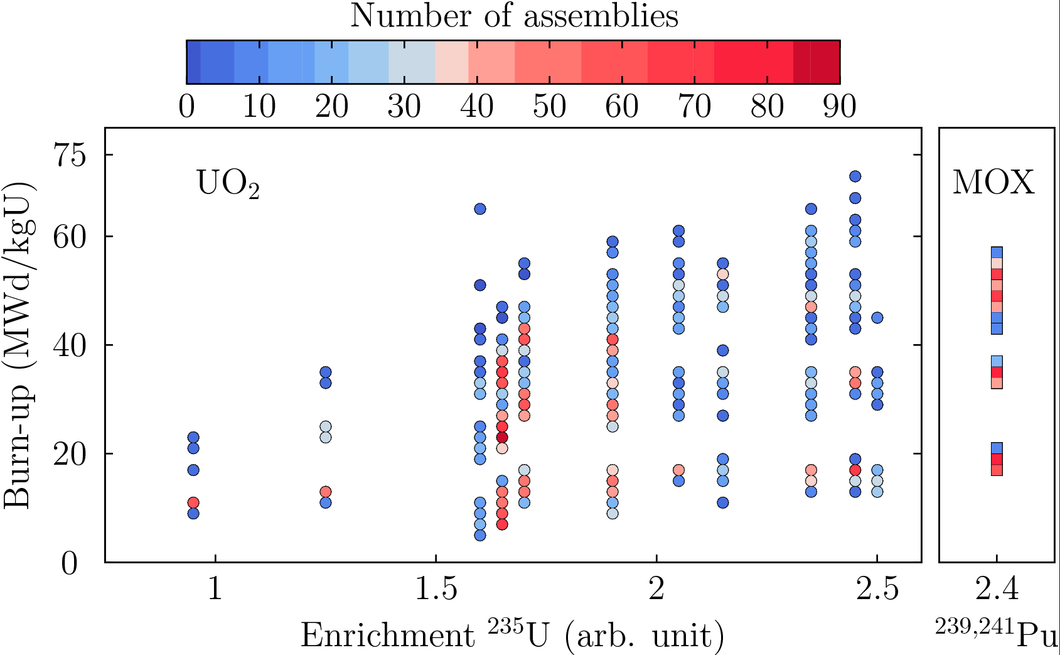

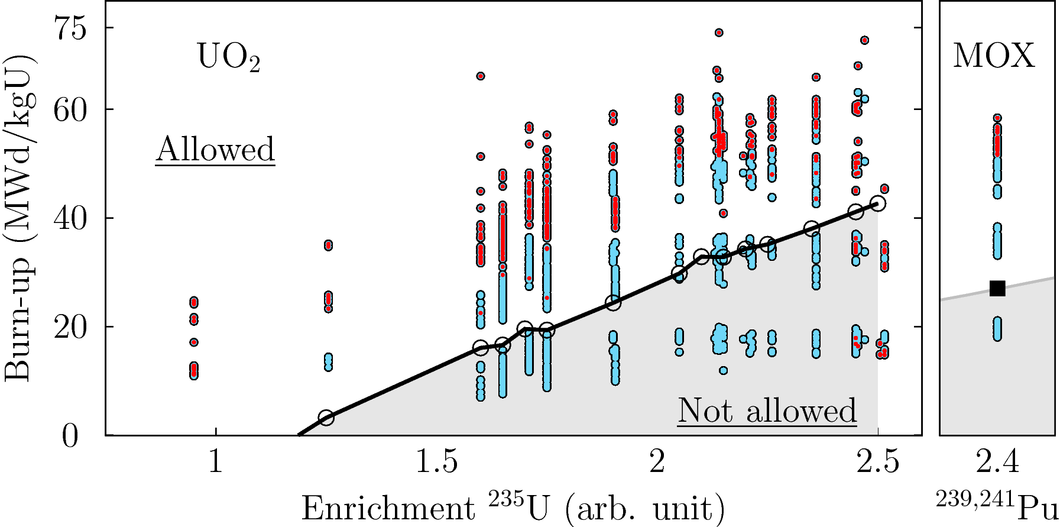

The number of UO2 and MOX assemblies for a real Swiss Pressurized Water Reactor (PWR) is presented in Fig. 1 as a representative example.

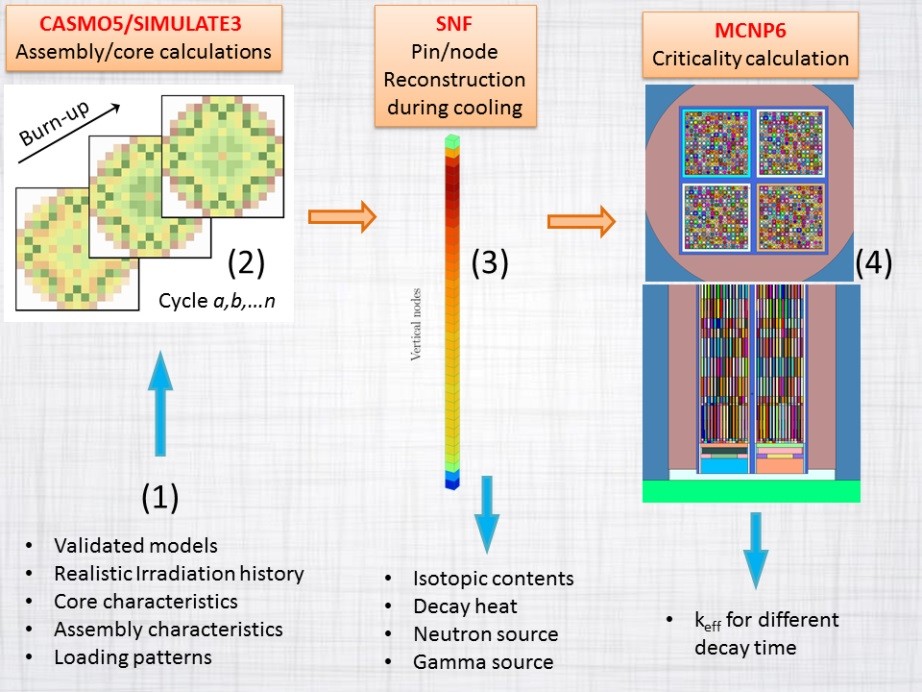

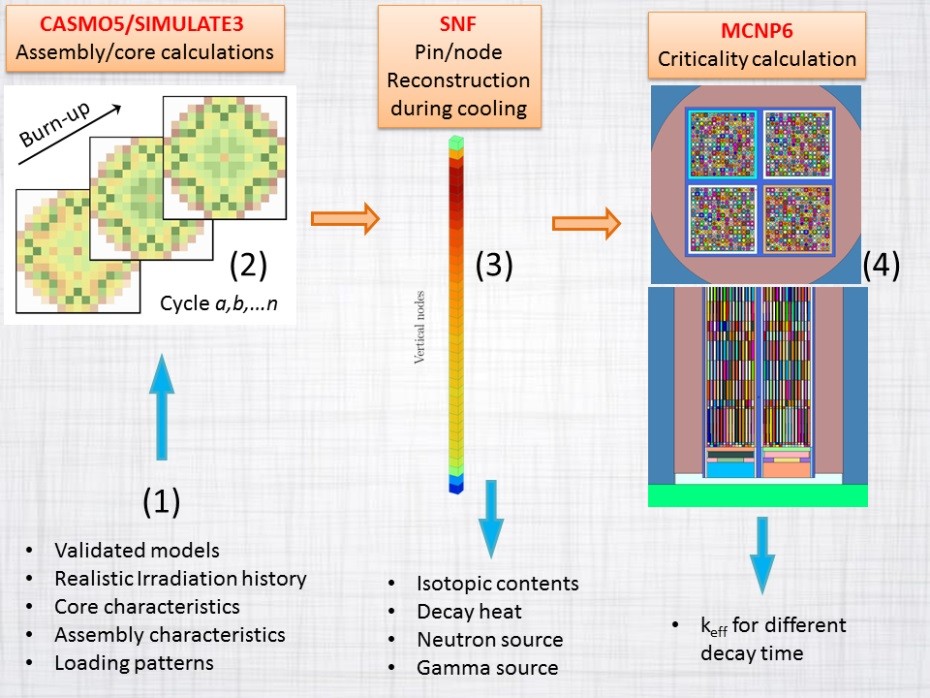

The method proposed in this work is summarized in Fig. 2, allowing to consistently calculate criticality quantities (being the neutron multiplication factor keff), emission source (neutron and gamma) and decay heat. Such approach can provide these quantities considering the individual history of each irradiated fuel assembly and is articulated around the four following steps:

- each assembly, core and cycle is represented by validated models and data,

- these CASMO/SIMULATE models are applied to reconstruct the lattice data file with isotope concentrations and power history data file,

- the SNF code is using the previous information to provide individual isotopic concentrations for each pin and segment, together with the assembly neutron/gamma source and decay heat quantities, for different cooling times,

- the isotopic concentrations for each cooling time is passed to a MCNP model (for each pin and vertical segment) for a specific canister, allowing to calculate keff.

Application to a Reference Pressurized Water Reactor (PWR)

To illustrate the capabilities of this approach, as mentioned, a reference PWR core is considered where both UO2 and MOX fuel assemblies have been operated. This study spans over 34 reactor cycles, representing about 35 years of operation. In total, close to 2000 assemblies were used in multiple cycles, being more than 6000 assembly-cycles (90% UO2 and 10% MOX). To cover a large range of assembly burnup values, the present criticality and radiation source calculations are performed for each assembly at the end of each cycle, being discharged for final disposal or not (see Fig. 1).

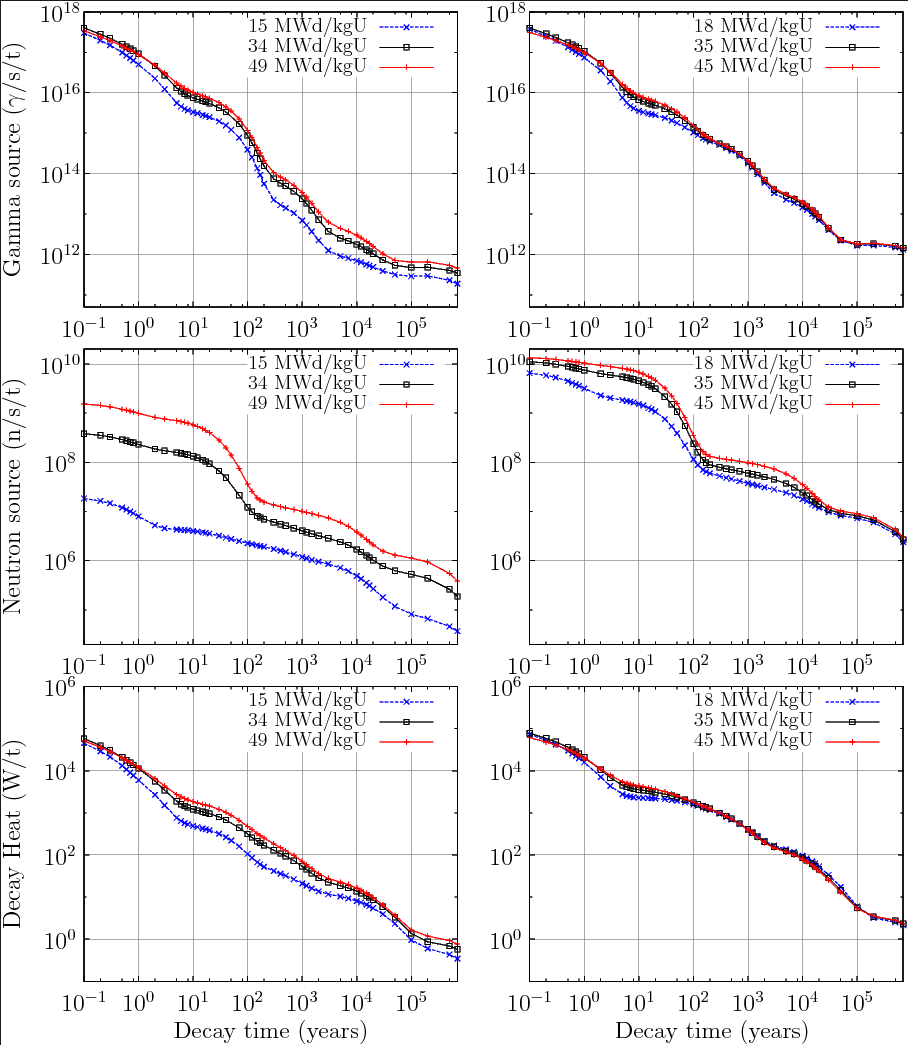

For the time being, only actinides are considered and fission products are therefore not accounted in the calculation of the radiation doses. This comes from the fact that the current version of the SNF code does not provide the full amount of fission products of interest (this is not the case with the latest version of this code). As an illustration, examples for two specific assemblies (one UO2 and one MOX) are presented in Fig. 3. As mentioned for the criticality calculations, it is assumed that the canister is loaded with four of the same assemblies. The calculations of criticality and radiation sources are also presented for different cooling times.

A loading curve is defining the limit between an acceptable canister loading (with a keff value lower than a given limit), and a loading leading to a keff value higher than the limit. In the following, the limit is fixed at keff = 0.95 (note that this value was taken as only an illustrative example, while the definition of a real "Upper Subcritical Limit" applied in practice goes beyond the scope of the present discussion). To calculate the loading curve, an MCNP model is used to calculate keff, with four equal assemblies. Inserting the same assemblies together in the canister is a simplification with the only purpose of avoiding an optimization step (e.g. to minimize specific radiation quantities). In a realistic canister loading, all assemblies will be different. By performing such study for all assemblies previously presented, a loading curve can be obtained, as presented in Fig. 4.

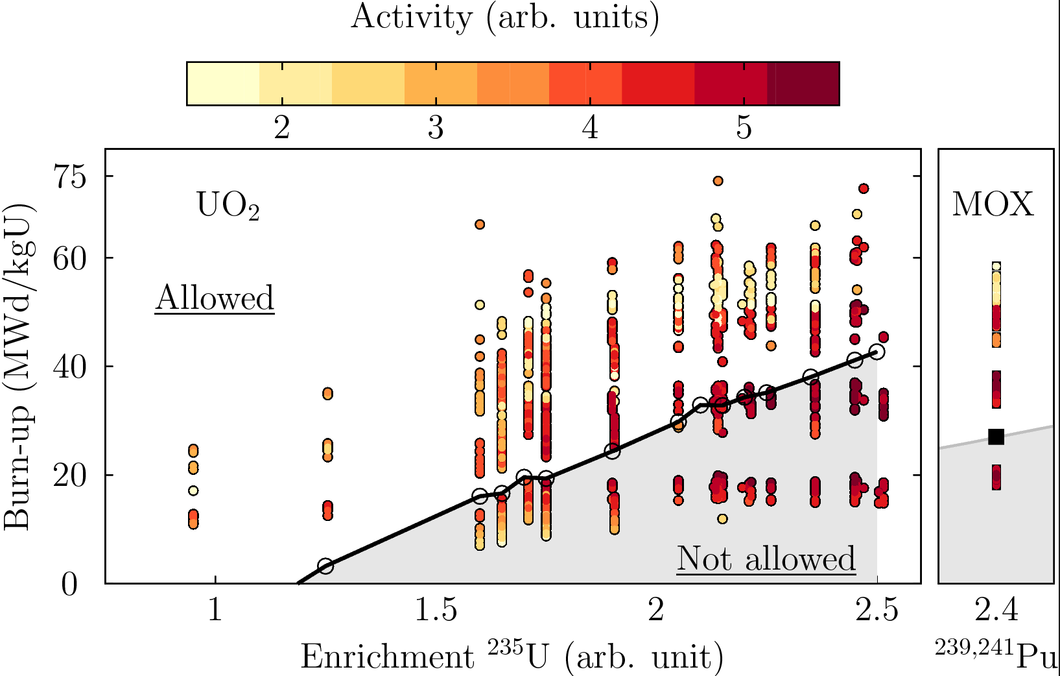

As the radiation sources are calculated for each assembly-cycle, the quantities such as activities, decay heat, and the neutron & gamma emissions can be compared with the keff values. An example of comparison with the calculated activity is presented in Fig.5. Note that the quoted activity is given for a single assembly and not for the canister. Also, as this study represents the case of “actinides only” for the criticality study, the following comparisons need to be extended to the case “actinides and fission products” to be relevant to realistic studies.

As a conclusion, this new study presents the possibility to calculate radiation quantities for spent fuel assemblies and criticality values for their handling and storage, based on their specific assembly isotopic inventory. Such inventory comes from an in-core fuel management system, validated core models and on four state-of-the-art codes: CASMO, SIMULATE, SNF and MCNP6. The importance of the assembly irradiation history was illustrated, notably of the cooling time between cycle for the assembly activity, decay heat and gamma emission. By considering the specific assembly histories, optimization for canister loading can be done for criticality, activity and decay heat in order to minimize risks and environmental irradiation. In a follow-up study, the case of heterogeneous assembly loading will need to be analyzed for the minimization of criticality risk and radiation emission. Also, the case of “actinides only” for criticality study will be extended to “actinides and fission products”. And finally, as this work is based on a fully automated scheme from the first irradiation of a specific assembly to its final disposal, a full uncertainty propagation can be performed, for instance by taking into account the variation of nuclear data.